Page 241 - An Introduction to Microelectromechanical Systems Engineering

P. 241

220 Packaging and Reliability Considerations for MEMS

provided the vibrations are not sufficiently large to cause damage. In addition to

mechanical protection, an electrically grounded cover also shields against electro-

magnetic interference (EMI). Naturally, the cap approach is not suitable for sensors,

such as pressure or flow sensors, or actuators that require direct and immediate con-

tact with their surrounding environments.

Thermal Management

The demands on thermal management can be very diverse and occasionally conflict-

ing depending on the nature of the application. The main role of thermal manage-

ment for electronic packaging is to cool the integrated circuit during operation [1]. A

modern microprocessor containing millions of transistors and operating at a few

gigahertz can consume tens of watts. By contrast, the role of thermal management in

MEMS includes the cooling of heat-dissipating devices and, especially, thermal

actuators, but it also involves understanding and accounting for the sources of tem-

perature fluctuations that may adversely affect the performance of a sensor or actua-

tor. As such, thermal management is performed at two levels: the die level and the

package level.

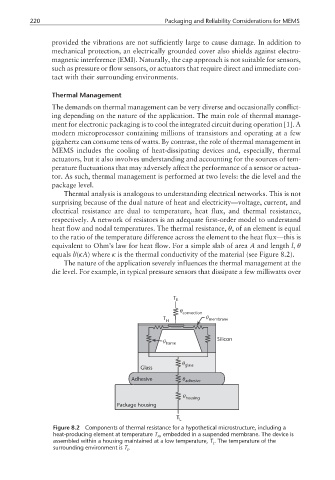

Thermal analysis is analogous to understanding electrical networks. This is not

surprising because of the dual nature of heat and electricity—voltage, current, and

electrical resistance are dual to temperature, heat flux, and thermal resistance,

respectively. A network of resistors is an adequate first-order model to understand

heat flow and nodal temperatures. The thermal resistance, θ, of an element is equal

to the ratio of the temperature difference across the element to the heat flux—this is

equivalent to Ohm’s law for heat flow. For a simple slab of area A and length l, θ

equals l/(κA) where κ is the thermal conductivity of the material (see Figure 8.2).

The nature of the application severely influences the thermal management at the

die level. For example, in typical pressure sensors that dissipate a few milliwatts over

T E

θ convection

T θ membrane

H

θ frame Silicon

θ glass

Glass

Adhesive θ adhesive

θ housing

Package housing

T L

Figure 8.2 Components of thermal resistance for a hypothetical microstructure, including a

heat-producing element at temperature T , embedded in a suspended membrane. The device is

H

assembled within a housing maintained at a low temperature, T . The temperature of the

L

surrounding environment is T .

E