Page 264 - An Introduction to Microelectromechanical Systems Engineering

P. 264

Quality Control, Reliability, and Failure Analysis 243

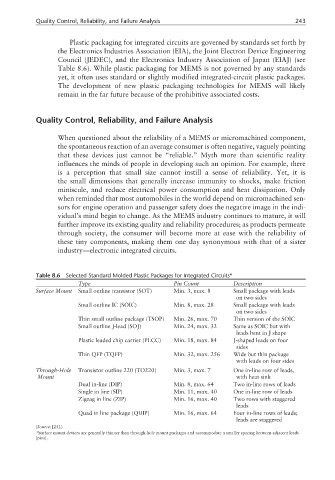

Plastic packaging for integrated circuits are governed by standards set forth by

the Electronics Industries Association (EIA), the Joint Electron Device Engineering

Council (JEDEC), and the Electronics Industry Association of Japan (EIAJ) (see

Table 8.6). While plastic packaging for MEMS is not governed by any standards

yet, it often uses standard or slightly modified integrated-circuit plastic packages.

The development of new plastic packaging technologies for MEMS will likely

remain in the far future because of the prohibitive associated costs.

Quality Control, Reliability, and Failure Analysis

When questioned about the reliability of a MEMS or micromachined component,

the spontaneous reaction of an average consumer is often negative, vaguely pointing

that these devices just cannot be “reliable.” Myth more than scientific reality

influences the minds of people in developing such an opinion. For example, there

is a perception that small size cannot instill a sense of reliability. Yet, it is

the small dimensions that generally increase immunity to shocks, make friction

miniscule, and reduce electrical power consumption and heat dissipation. Only

when reminded that most automobiles in the world depend on micromachined sen-

sors for engine operation and passenger safety does the negative image in the indi-

vidual’s mind begin to change. As the MEMS industry continues to mature, it will

further improve its existing quality and reliability procedures; as products permeate

through society, the consumer will become more at ease with the reliability of

these tiny components, making them one day synonymous with that of a sister

industry—electronic integrated circuits.

Table 8.6 Selected Standard Molded Plastic Packages for Integrated Circuits*

Type Pin Count Description

Surface Mount Small outline transistor (SOT) Min. 3, max. 8 Small package with leads

on two sides

Small outline IC (SOIC) Min. 8, max. 28 Small package with leads

on two sides

Thin small outline package (TSOP) Min. 26, max. 70 Thin version of the SOIC

Small outline J-lead (SOJ) Min. 24, max. 32 Same as SOIC but with

leads bent in J shape

Plastic leaded chip carrier (PLCC) Min. 18, max. 84 J-shaped leads on four

sides

Thin QFP (TQFP) Min. 32, max. 256 Wide but thin package

with leads on four sides

Through-Hole Transistor outline 220 (TO220) Min. 3, max. 7 One in-line row of leads,

Mount with heat sink

Dual in-line (DIP) Min. 8, max. 64 Two in-line rows of leads

Single in line (SIP) Min. 11, max. 40 One in-line row of leads

Zigzag in line (ZIP) Min. 16, max. 40 Two rows with staggered

leads

Quad in line package (QUIP) Min. 16, max. 64 Four in-line rows of leads;

leads are staggered

(Source: [25].)

*Surface mount devices are generally thinner than through-hole mount packages and accommodate a smaller spacing between adjacent leads

(pins).