Page 266 - An Introduction to Microelectromechanical Systems Engineering

P. 266

Quality Control, Reliability, and Failure Analysis 245

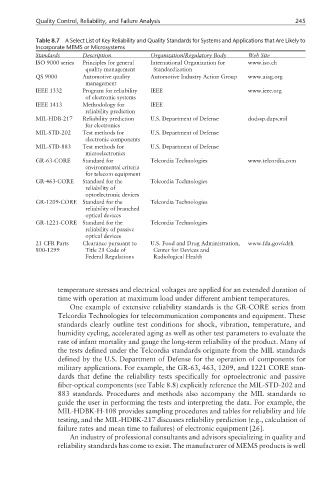

Table 8.7 A Select List of Key Reliability and Quality Standards for Systems and Applications that Are Likely to

Incorporate MEMS or Microsystems

Standards Description Organization/Regulatory Body Web Site

ISO 9000 series Principles for general International Organization for www.iso.ch

quality management Standardization

QS 9000 Automotive quality Automotive Industry Action Group www.aiag.org

management

IEEE 1332 Program for reliability IEEE www.ieee.org

of electronic systems

IEEE 1413 Methodology for IEEE

reliability prediction

MIL-HDB-217 Reliability prediction U.S. Department of Defense dodssp.daps.mil

for electronics

MIL-STD-202 Test methods for U.S. Department of Defense

electronic components

MIL-STD-883 Test methods for U.S. Department of Defense

microelectronics

GR-63-CORE Standard for Telcordia Technologies www.telcordia.com

environmental criteria

for telecom equipment

GR-463-CORE Standard for the Telcordia Technologies

reliability of

optoelectronic devices

GR-1209-CORE Standard for the Telcordia Technologies

reliability of branched

optical devices

GR-1221-CORE Standard for the Telcordia Technologies

reliability of passive

optical devices

21 CFR Parts Clearance pursuant to U.S. Food and Drug Administration, www.fda.gov/cdrh

800-1299 Title 21 Code of Center for Devices and

Federal Regulations Radiological Health

temperature stresses and electrical voltages are applied for an extended duration of

time with operation at maximum load under different ambient temperatures.

One example of extensive reliability standards is the GR-CORE series from

Telcordia Technologies for telecommunication components and equipment. These

standards clearly outline test conditions for shock, vibration, temperature, and

humidity cycling, accelerated aging as well as other test parameters to evaluate the

rate of infant mortality and gauge the long-term reliability of the product. Many of

the tests defined under the Telcordia standards originate from the MIL standards

defined by the U.S. Department of Defense for the operation of components for

military applications. For example, the GR-63, 463, 1209, and 1221 CORE stan-

dards that define the reliability tests specifically for optoelectronic and passive

fiber-optical components (see Table 8.8) explicitly reference the MIL-STD-202 and

883 standards. Procedures and methods also accompany the MIL standards to

guide the user in performing the tests and interpreting the data. For example, the

MIL-HDBK-H-108 provides sampling procedures and tables for reliability and life

testing, and the MIL-HDBK-217 discusses reliability prediction (e.g., calculation of

failure rates and mean time to failures) of electronic equipment [26].

An industry of professional consultants and advisors specializing in quality and

reliability standards has come to exist. The manufacturer of MEMS products is well