Page 261 - An Introduction to Microelectromechanical Systems Engineering

P. 261

240 Packaging and Reliability Considerations for MEMS

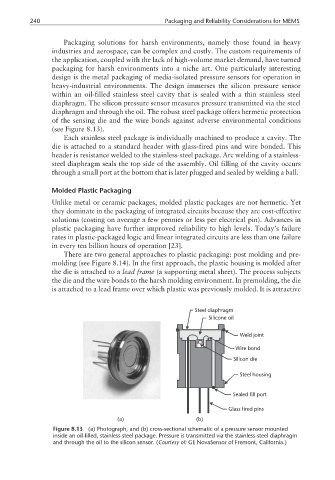

Packaging solutions for harsh environments, namely those found in heavy

industries and aerospace, can be complex and costly. The custom requirements of

the application, coupled with the lack of high-volume market demand, have turned

packaging for harsh environments into a niche art. One particularly interesting

design is the metal packaging of media-isolated pressure sensors for operation in

heavy-industrial environments. The design immerses the silicon pressure sensor

within an oil-filled stainless steel cavity that is sealed with a thin stainless steel

diaphragm. The silicon pressure sensor measures pressure transmitted via the steel

diaphragm and through the oil. The robust steel package offers hermetic protection

of the sensing die and the wire bonds against adverse environmental conditions

(see Figure 8.13).

Each stainless steel package is individually machined to produce a cavity. The

die is attached to a standard header with glass-fired pins and wire bonded. This

header is resistance welded to the stainless-steel package. Arc welding of a stainless-

steel diaphragm seals the top side of the assembly. Oil filling of the cavity occurs

through a small port at the bottom that is later plugged and sealed by welding a ball.

Molded Plastic Packaging

Unlike metal or ceramic packages, molded plastic packages are not hermetic. Yet

they dominate in the packaging of integrated circuits because they are cost-effective

solutions (costing on average a few pennies or less per electrical pin). Advances in

plastic packaging have further improved reliability to high levels. Today’s failure

rates in plastic-packaged logic and linear integrated circuits are less than one failure

in every ten billion hours of operation [23].

There are two general approaches to plastic packaging: post molding and pre-

molding (see Figure 8.14). In the first approach, the plastic housing is molded after

the die is attached to a lead frame (a supporting metal sheet). The process subjects

the die and the wire bonds to the harsh molding environment. In premolding, the die

is attached to a lead frame over which plastic was previously molded. It is attractive

Steel diaphragm

Silicone oil

Weld joint

Wire bond

Silicon die

Steel housing

Sealed fill port

Glass fired pins

(a) (b)

Figure 8.13 (a) Photograph, and (b) cross-sectional schematic of a pressure sensor mounted

inside an oil-filled, stainless-steel package. Pressure is transmitted via the stainless-steel diaphragm

and through the oil to the silicon sensor. (Courtesy of: GE NovaSensor of Fremont, California.)