Page 258 - An Introduction to Microelectromechanical Systems Engineering

P. 258

Types of Packaging Solutions 237

Gel Thick-film

resistor

Plastic cap

Ceramic

Figure 8.9 Photograph of a disposable blood pressure sensor for arterial-line measurement in

intensive care units. The die (not visible) sits on a ceramic substrate and is covered with a plastic

cap that includes an access opening for pressure. A special black gel dispensed inside the opening

protects the silicon device while permitting the transmission of pressure. (Courtesy of: GE

NovaSensor, Fremont, California [21].)

Hermetic optical window (Corning 7056) Gold wire bonds

DMD

Glass-to-metal fused seal

Kovar frame

Seam weld

Kovar seal ring

Ceramic header Zeolite getters

Heat sink

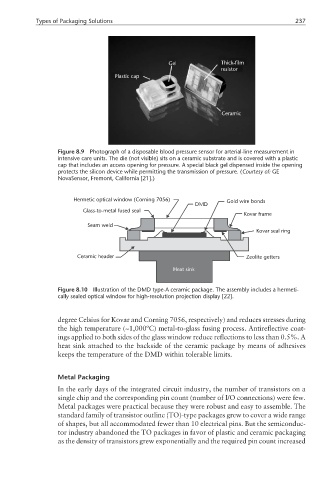

Figure 8.10 Illustration of the DMD type-A ceramic package. The assembly includes a hermeti-

cally sealed optical window for high-resolution projection display [22].

degree Celsius for Kovar and Corning 7056, respectively) and reduces stresses during

the high temperature (~1,000ºC) metal-to-glass fusing process. Antireflective coat-

ings applied to both sides of the glass window reduce reflections to less than 0.5%. A

heat sink attached to the backside of the ceramic package by means of adhesives

keeps the temperature of the DMD within tolerable limits.

Metal Packaging

In the early days of the integrated circuit industry, the number of transistors on a

single chip and the corresponding pin count (number of I/O connections) were few.

Metal packages were practical because they were robust and easy to assemble. The

standard family of transistor outline (TO)-type packages grew to cover a wide range

of shapes, but all accommodated fewer than 10 electrical pins. But the semiconduc-

tor industry abandoned the TO packages in favor of plastic and ceramic packaging

as the density of transistors grew exponentially and the required pin count increased