Page 253 - An Introduction to Microelectromechanical Systems Engineering

P. 253

232 Packaging and Reliability Considerations for MEMS

Optical Interconnects

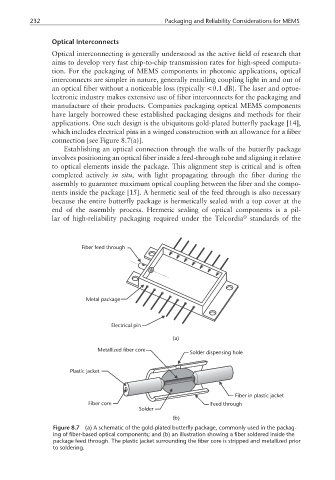

Optical interconnecting is generally understood as the active field of research that

aims to develop very fast chip-to-chip transmission rates for high-speed computa-

tion. For the packaging of MEMS components in photonic applications, optical

interconnects are simpler in nature, generally entailing coupling light in and out of

an optical fiber without a noticeable loss (typically <0.1 dB). The laser and optoe-

lectronic industry makes extensive use of fiber interconnects for the packaging and

manufacture of their products. Companies packaging optical MEMS components

have largely borrowed these established packaging designs and methods for their

applications. One such design is the ubiquitous gold-plated butterfly package [14],

which includes electrical pins in a winged construction with an allowance for a fiber

connection [see Figure 8.7(a)].

Establishing an optical connection through the walls of the butterfly package

involves positioning an optical fiber inside a feed-through tube and aligning it relative

to optical elements inside the package. This alignment step is critical and is often

completed actively in situ, with light propagating through the fiber during the

assembly to guarantee maximum optical coupling between the fiber and the compo-

nents inside the package [15]. A hermetic seal of the feed through is also necessary

because the entire butterfly package is hermetically sealed with a top cover at the

end of the assembly process. Hermetic sealing of optical components is a pil-

®

lar of high-reliability packaging required under the Telcordia standards of the

Fiber feed through

Metal package

Electrical pin

(a)

Metallized fiber core

Solder dispensing hole

Plastic jacket

Fiber in plastic jacket

Fiber core Feed through

Solder

(b)

Figure 8.7 (a) A schematic of the gold-plated butterfly package, commonly used in the packag-

ing of fiber-based optical components; and (b) an illustration showing a fiber soldered inside the

package feed through. The plastic jacket surrounding the fiber core is stripped and metallized prior

to soldering.