Page 250 - An Introduction to Microelectromechanical Systems Engineering

P. 250

Wiring and Interconnects 229

Gold wire

generator Wire clamp Force Gold wire

Bonding tip

Arc

Bondpad

Die Die Package lead

1. Arcing forms 2. Ball bond while applying 3. Position tip over package lead

gold ball heat and/or ultrasonic

Force

Wire loop

Die Package lead

4. Stitch bond on lead 5. Break wire

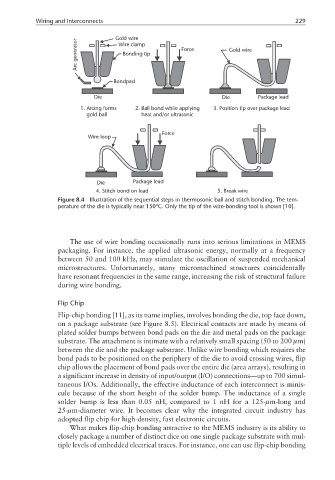

Figure 8.4 Illustration of the sequential steps in thermosonic ball and stitch bonding. The tem-

perature of the die is typically near 150ºC. Only the tip of the wire-bonding tool is shown [10].

The use of wire bonding occasionally runs into serious limitations in MEMS

packaging. For instance, the applied ultrasonic energy, normally at a frequency

between 50 and 100 kHz, may stimulate the oscillation of suspended mechanical

microstructures. Unfortunately, many micromachined structures coincidentally

have resonant frequencies in the same range, increasing the risk of structural failure

during wire bonding.

Flip Chip

Flip-chip bonding [11], as its name implies, involves bonding the die, top face down,

on a package substrate (see Figure 8.5). Electrical contacts are made by means of

plated solder bumps between bond pads on the die and metal pads on the package

substrate. The attachment is intimate with a relatively small spacing (50 to 200 µm)

between the die and the package substrate. Unlike wire bonding which requires the

bond pads to be positioned on the periphery of the die to avoid crossing wires, flip

chip allows the placement of bond pads over the entire die (area arrays), resulting in

a significant increase in density of input/output (I/O) connections—up to 700 simul-

taneous I/Os. Additionally, the effective inductance of each interconnect is minis-

cule because of the short height of the solder bump. The inductance of a single

solder bump is less than 0.05 nH, compared to 1 nH for a 125-µm-long and

25-µm-diameter wire. It becomes clear why the integrated circuit industry has

adopted flip chip for high-density, fast electronic circuits.

What makes flip-chip bonding attractive to the MEMS industry is its ability to

closely package a number of distinct dice on one single package substrate with mul-

tiple levels of embedded electrical traces. For instance, one can use flip-chip bonding