Page 46 - An Introduction to Microelectromechanical Systems Engineering

P. 46

Important Material Properties and Physical Effects 25

Parallel direction

Sense element

Alignment

marks

Backing film

Orthogonal

direction

Solder

tab

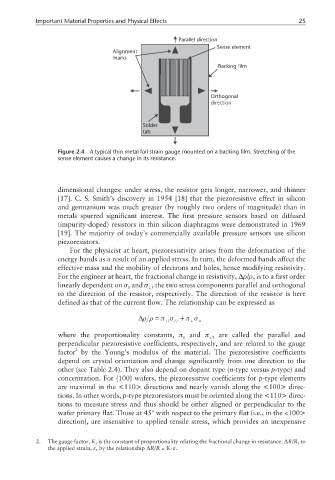

Figure 2.4 A typical thin metal foil strain gauge mounted on a backing film. Stretching of the

sense element causes a change in its resistance.

dimensional changes: under stress, the resistor gets longer, narrower, and thinner

[17]. C. S. Smith’s discovery in 1954 [18] that the piezoresistive effect in silicon

and germanium was much greater (by roughly two orders of magnitude) than in

metals spurred significant interest. The first pressure sensors based on diffused

(impurity-doped) resistors in thin silicon diaphragms were demonstrated in 1969

[19]. The majority of today’s commercially available pressure sensors use silicon

piezoresistors.

For the physicist at heart, piezoresistivity arises from the deformation of the

energy bands as a result of an applied stress. In turn, the deformed bands affect the

effective mass and the mobility of electrons and holes, hence modifying resistivity.

For the engineer at heart, the fractional change in resistivity, ∆ρ/ρ, is to a first order

linearly dependent on σ and σ , the two stress components parallel and orthogonal

// ⊥

to the direction of the resistor, respectively. The direction of the resistor is here

defined as that of the current flow. The relationship can be expressed as

∆ρ ρ= π σ + π σ ⊥

⊥

//

//

where the proportionality constants, π and π , are called the parallel and

⊥

//

perpendicular piezoresistive coefficients, respectively, and are related to the gauge

2

factor by the Young’s modulus of the material. The piezoresistive coefficients

depend on crystal orientation and change significantly from one direction to the

other (see Table 2.4). They also depend on dopant type (n-type versus p-type) and

concentration. For {100} wafers, the piezoresistive coefficients for p-type elements

are maximal in the <110> directions and nearly vanish along the <100> direc-

tions. In other words, p-type piezoresistors must be oriented along the <110> direc-

tions to measure stress and thus should be either aligned or perpendicular to the

wafer primary flat. Those at 45º with respect to the primary flat (i.e., in the <100>

direction), are insensitive to applied tensile stress, which provides an inexpensive

2. The gauge factor, K, is the constant of proportionality relating the fractional change in resistance, ∆R/R,to

the applied strain, ε, by the relationship ∆R/R = K⋅ε.