Page 143 - Analysis and Design of Machine Elements

P. 143

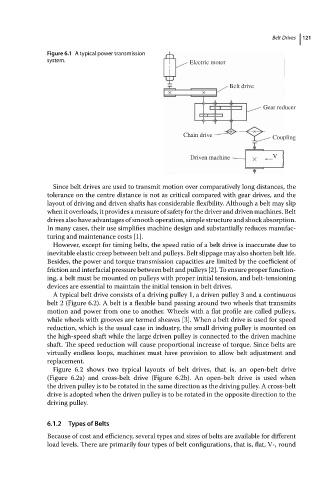

Figure 6.1 A typical power transmission Belt Drives 121

system. Electric motor

Belt drive

Gear reducer

Chain drive Coupling

Driven machine V

Since belt drives are used to transmit motion over comparatively long distances, the

toleranceonthe centre distance is notascriticalcomparedwithgeardrives, andthe

layout of driving and driven shafts has considerable flexibility. Although a belt may slip

when it overloads, it provides a measure of safety for the driver and driven machines. Belt

drives also have advantages of smooth operation, simple structure and shock absorption.

In many cases, their use simplifies machine design and substantially reduces manufac-

turing and maintenance costs [1].

However, except for timing belts, the speed ratio of a belt drive is inaccurate due to

inevitable elastic creep between belt and pulleys. Belt slippage may also shorten belt life.

Besides, the power and torque transmission capacities are limited by the coefficient of

friction and interfacial pressure between belt and pulleys [2]. To ensure proper function-

ing, a belt must be mounted on pulleys with proper initial tension, and belt-tensioning

devices are essential to maintain the initial tension in belt drives.

A typical belt drive consists of a driving pulley 1, a driven pulley 3 and a continuous

belt 2 (Figure 6.2). A belt is a flexible band passing around two wheels that transmits

motion and power from one to another. Wheels with a flat profile are called pulleys,

while wheels with grooves are termed sheaves [3]. When a belt drive is used for speed

reduction, which is the usual case in industry, the small driving pulley is mounted on

the high-speed shaft while the large driven pulley is connected to the driven machine

shaft. The speed reduction will cause proportional increase of torque. Since belts are

virtually endless loops, machines must have provision to allow belt adjustment and

replacement.

Figure 6.2 shows two typical layouts of belt drives, that is, an open-belt drive

(Figure 6.2a) and cross-belt drive (Figure 6.2b). An open-belt drive is used when

the driven pulley is to be rotated in the same direction as the driving pulley. A cross-belt

drive is adopted when the driven pulley is to be rotated in the opposite direction to the

driving pulley.

6.1.2 Types of Belts

Because of cost and efficiency, several types and sizes of belts are available for different

load levels. There are primarily four types of belt configurations, that is, flat, V-, round