Page 144 - Analysis and Design of Machine Elements

P. 144

Analysis and Design of Machine Elements

122

v

v n 2

n 1 n 1

v

n 2

v

1 2 3 1 2 3

(a) Open - belt drive (b) Cross - belt drive

Figure 6.2 Typical belt drive layouts.

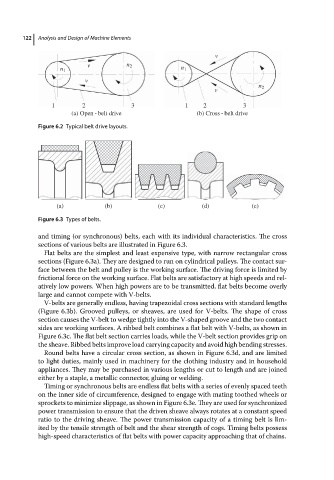

(a) (b) (c) (d) (e)

Figure 6.3 Types of belts.

and timing (or synchronous) belts, each with its individual characteristics. The cross

sections of various belts are illustrated in Figure 6.3.

Flat belts are the simplest and least expensive type, with narrow rectangular cross

sections (Figure 6.3a). They are designed to run on cylindrical pulleys. The contact sur-

face between the belt and pulley is the working surface. The driving force is limited by

frictional force on the working surface. Flat belts are satisfactory at high speeds and rel-

atively low powers. When high powers are to be transmitted, flat belts become overly

large and cannot compete with V-belts.

V-belts are generally endless, having trapezoidal cross sections with standard lengths

(Figure 6.3b). Grooved pulleys, or sheaves, are used for V-belts. The shape of cross

section causes the V-belt to wedge tightly into the V-shaped groove and the two contact

sides are working surfaces. A ribbed belt combines a flat belt with V-belts, as shown in

Figure 6.3c. The flat belt section carries loads, while the V-belt section provides grip on

the sheave. Ribbed belts improve load carrying capacity and avoid high bending stresses.

Round belts have a circular cross section, as shown in Figure 6.3d, and are limited

to light duties, mainly used in machinery for the clothing industry and in household

appliances. They may be purchased in various lengths or cut to length and are joined

either by a staple, a metallic connector, gluing or welding.

Timing or synchronous belts are endless flat belts with a series of evenly spaced teeth

on the inner side of circumference, designed to engage with mating toothed wheels or

sprockets to minimize slippage, as shown in Figure 6.3e. They are used for synchronized

power transmission to ensure that the driven sheave always rotates at a constant speed

ratio to the driving sheave. The power transmission capacity of a timing belt is lim-

ited by the tensile strength of belt and the shear strength of cogs. Timing belts possess

high-speed characteristics of flat belts with power capacity approaching that of chains.