Page 257 - Analysis and Design of Machine Elements

P. 257

a Wormgear Drives 235

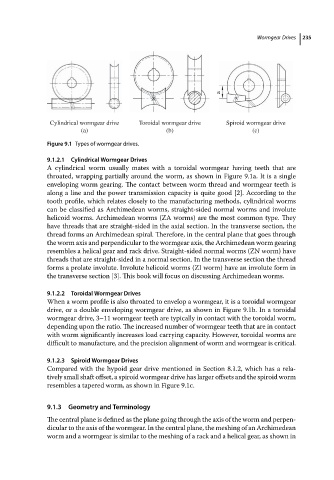

Cylindrical wormgear drive Toroidal wormgear drive Spiroid wormgear drive

(a) (b) (c)

Figure 9.1 Types of wormgear drives.

9.1.2.1 Cylindrical Wormgear Drives

A cylindrical worm usually mates with a toroidal wormgear having teeth that are

throated, wrapping partially around the worm, as shown in Figure 9.1a. It is a single

enveloping worm gearing. The contact between worm thread and wormgear teeth is

along a line and the power transmission capacity is quite good [2]. According to the

tooth profile, which relates closely to the manufacturing methods, cylindrical worms

can be classified as Archimedean worms, straight-sided normal worms and involute

helicoid worms. Archimedean worms (ZA worms) are the most common type. They

have threads that are straight-sided in the axial section. In the transverse section, the

thread forms an Archimedean spiral. Therefore, in the central plane that goes through

the worm axis and perpendicular to the wormgear axis, the Archimedean worm gearing

resembles a helical gear and rack drive. Straight-sided normal worms (ZN worm) have

threads that are straight-sided in a normal section. In the transverse section the thread

forms a prolate involute. Involute helicoid worms (ZI worm) have an involute form in

the transverse section [3]. This book will focus on discussing Archimedean worms.

9.1.2.2 Toroidal Wormgear Drives

When a worm profile is also throated to envelop a wormgear, it is a toroidal wormgear

drive, or a double enveloping wormgear drive, as shown in Figure 9.1b. In a toroidal

wormgear drive, 3–11 wormgear teeth are typically in contact with the toroidal worm,

depending upon the ratio. The increased number of wormgear teeth that are in contact

with worm significantly increases load carrying capacity. However, toroidal worms are

difficult to manufacture, and the precision alignment of worm and wormgear is critical.

9.1.2.3 Spiroid Wormgear Drives

Compared with the hypoid gear drive mentioned in Section 8.1.2, which has a rela-

tively small shaft offset, a spiroid wormgear drive has larger offsets and the spiroid worm

resembles a tapered worm, as shown in Figure 9.1c.

9.1.3 Geometry and Terminology

The central plane is defined as the plane going through the axis of the worm and perpen-

dicular to the axis of the wormgear. In the central plane, the meshing of an Archimedean

worm and a wormgear is similar to the meshing of a rack and a helical gear, as shown in