Page 261 - Analysis and Design of Machine Elements

P. 261

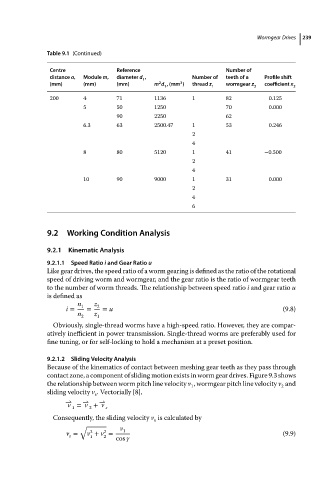

Table 9.1 (Continued) Wormgear Drives 239

Centre Reference Number of

distance a, Module m, diameter d , Number of teeth of a Profile shift

1

2

3

(mm) (mm) (mm) m d ,(mm ) thread z wormgear z coefficient x

1 1 2 2

200 4 71 1136 1 82 0.125

5 50 1250 70 0.000

90 2250 62

6.3 63 2500.47 1 53 0.246

2

4

8 80 5120 1 41 −0.500

2

4

10 90 9000 1 31 0.000

2

4

6

9.2 Working Condition Analysis

9.2.1 Kinematic Analysis

9.2.1.1 Speed Ratio i and Gear Ratio u

Like gear drives, the speed ratio of a worm gearing is defined as the ratio of the rotational

speed of driving worm and wormgear, and the gear ratio is the ratio of wormgear teeth

to the number of worm threads. The relationship between speed ratio i and gear ratio u

is defined as

n 1 z 2

i = = = u (9.8)

n 2 z 1

Obviously, single-thread worms have a high-speed ratio. However, they are compar-

atively inefficient in power transmission. Single-thread worms are preferably used for

fine tuning, or for self-locking to hold a mechanism at a preset position.

9.2.1.2 Sliding Velocity Analysis

Because of the kinematics of contact between meshing gear teeth as they pass through

contact zone, a component of sliding motion exists in worm gear drives. Figure 9.3 shows

the relationship between worm pitch line velocity v , wormgear pitch line velocity v and

1 2

sliding velocity v . Vectorially [8],

s

− ⇀ − ⇀ − ⇀

v = v + v s

1

2

Consequently, the sliding velocity v is calculated by

s

√ v

2

2

v = v + v = 1 (9.9)

s

2

1

cos