Page 289 - Analysis and Design of Machine Elements

P. 289

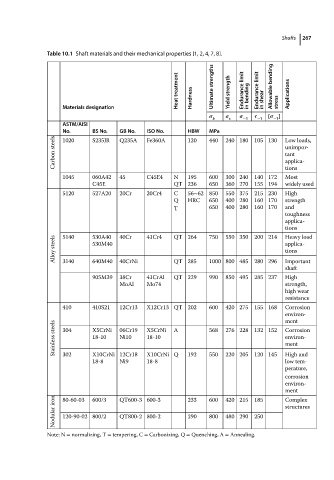

Table 10.1 Shaft materials and their mechanical properties [1, 2, 4, 7, 8]. Shafts 267

Heat treatment Hardness Ultimate strengths Yield strength Endurance limit in bending Endurance limit Allowable bending Applications

Materials designation in shear stress

b s −1 −1 [ ]

−1

ASTM/AISI

No. BS No. GB No. ISO No. HBW MPa

steels 1020 S235JR Q235A Fe360A 120 440 240 180 105 130 Low loads,

unimpor-

Carbon tant

applica-

tions

1045 060A42 45 C45E4 N 195 600 300 240 140 172 Most

C45E QT 236 650 360 270 155 194 widely used

5120 527A20 20Cr 20Cr4 C 56∼62 850 550 375 215 230 High

Q HRC 650 400 280 160 170 strength

T 650 400 280 160 170 and

toughness

applica-

tions

Alloy steels 530M40 applica-

5140 530A40 40Cr 41Cr4 QT 264 750 550 350 200 214 Heavy load

tions

280 296

640M40

QT 285

1000 800 485

Important

40CrNi

3140

shaft

905M39 38Cr 41CrAl QT 229 990 850 495 285 237 High

MoAl Mo74 strength,

high wear

resistance

410 410S21 12Cr13 X12Cr13 QT 202 600 420 275 155 168 Corrosion

environ-

ment

Stainless steels 304 X5CrNi 06Cr19 X5CrNi A 568 276 228 132 152 Corrosion

18-10

Ni10

18-10

environ-

ment

X10CrNi 12Cr18

302

18-8 Ni9 X10CrNi Q 192 550 220 205 120 145 High and

low tem-

18-8

perature,

corrosion

environ-

ment

Nodular iron 120-90-02 800/2 QT800-2 800-2 290 800 480 290 250 structures

Complex

QT600-3 600-3

233

80-60-03

600/3

420 215

185

600

Note: N = normalizing, T = tempering, C = Carbonizing, Q = Quenching, A = Annealing.