Page 332 - Analysis and Design of Machine Elements

P. 332

Analysis and Design of Machine Elements

310

11.4 Design of Bearing Support Systems

11.4.1 Introduction

Shafts in a machine are usually supported by precisely produced and statistically tested

standardized rolling contact bearings. Apart from selecting appropriate bearings from

a commercially available inventory, the structural design of a bearing support system

is even more crucial for the successful operation of shafts and bearings. This section

discusses issues relevant to the mounting and application of bearings, covering the selec-

tion, installation, positioning, retaining, preloading, tolerance fit, lubrication and sealing

of bearings.

11.4.2 Bearing Selection

The selection of rolling contact bearings from a manufacturer’s catalogue involves the

determination of bearing types, dimensions and load carrying capacity for a given appli-

cation. The bearing type is selected according to the load amplitude and direction, speed

limitation, alignment requirement and cost, as discussed in Section 11.1.3.

The selection of bearing dimension considers load carrying capacity. To prevent fail-

ure, bearings must have sufficient resistance to surface fatigue failure, measured by basic

dynamic load rating C; and sufficient resistance to plastic deformation, measured by

basic static load rating C . These design criteria are universally used in characterizing

0

load carrying capacity for all types of rolling bearings. The values of basic dynamic load

rating C and basic static load rating C are tabulated in bearing catalogues. The cat-

0

alogues identify bearings by codes, basic sizes, mounting dimensions, capacity ratings

and so on, which help designers to select bearings that most efficiently and economically

fit the particular application. Table 11.2 tabulates basic dynamic load rating and basic

static load rating of selected bearing sizes of deep-groove ball bearings, angular contact

ball bearings and tapered roller bearings. More data can be found in manufacturers’

catalogues for bearings other than those listed in Table 11.2.

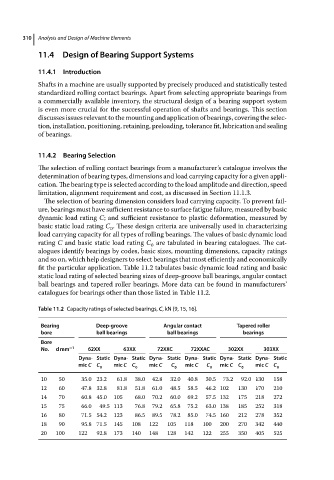

Table 11.2 Capacity ratings of selected bearings, C, kN [9, 15, 16].

Bearing Deep-groove Angular contact Tapered roller

bore ball bearings ball bearings bearings

Bore

No. d mm −1 62XX 63XX 72XXC 72XXAC 302XX 303XX

Dyna- Static Dyna- Static Dyna- Static Dyna- Static Dyna- Static Dyna- Static

mic C C 0 mic C C 0 mic C C 0 mic C C 0 mic C C 0 mic C C 0

10 50 35.0 23.2 61.8 38.0 42.8 32.0 40.8 30.5 73.2 92.0 130 158

12 60 47.8 32.8 81.8 51.8 61.0 48.5 58.5 46.2 102 130 170 210

14 70 60.8 45.0 105 68.0 70.2 60.0 69.2 57.5 132 175 218 272

15 75 66.0 49.5 113 76.8 79.2 65.8 75.2 63.0 138 185 252 318

16 80 71.5 54.2 123 86.5 89.5 78.2 85.0 74.5 160 212 278 352

18 90 95.8 71.5 145 108 122 105 118 100 200 270 342 440

20 100 122 92.8 173 140 148 128 142 122 255 350 405 525