Page 337 - Analysis and Design of Machine Elements

P. 337

(a) (b) Rolling Contact Bearings 315

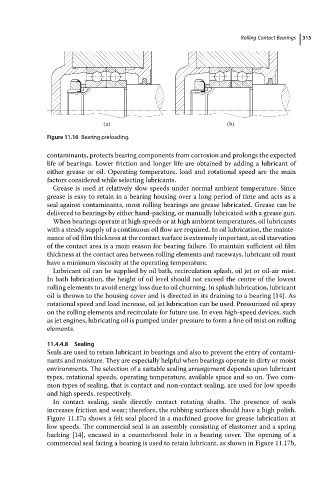

Figure 11.16 Bearing preloading.

contaminants, protects bearing components from corrosion and prolongs the expected

life of bearings. Lower friction and longer life are obtained by adding a lubricant of

either grease or oil. Operating temperature, load and rotational speed are the main

factors considered while selecting lubricants.

Grease is used at relatively slow speeds under normal ambient temperature. Since

grease is easy to retain in a bearing housing over a long period of time and acts as a

seal against contaminants, most rolling bearings are grease lubricated. Grease can be

delivered to bearings by either hand-packing, or manually lubricated with a grease gun.

When bearings operate at high speeds or at high ambient temperatures, oil lubricants

with a steady supply of a continuous oil flow are required. In oil lubrication, the mainte-

nance of oil film thickness at the contact surface is extremely important, as oil starvation

of the contact area is a main reason for bearing failure. To maintain sufficient oil film

thickness at the contact area between rolling elements and raceways, lubricant oil must

have a minimum viscosity at the operating temperature.

Lubricant oil can be supplied by oil bath, recirculation splash, oil jet or oil-air mist.

In bath lubrication, the height of oil level should not exceed the centre of the lowest

rolling elements to avoid energy loss due to oil churning. In splash lubrication, lubricant

oil is thrown to the housing cover and is directed in its draining to a bearing [14]. As

rotational speed and load increase, oil jet lubrication can be used. Pressurized oil spray

on the rolling elements and recirculate for future use. In even high-speed devices, such

as jet engines, lubricating oil is pumped under pressure to form a fine oil mist on rolling

elements.

11.4.4.8 Sealing

Seals are used to retain lubricant in bearings and also to prevent the entry of contami-

nants and moisture. They are especially helpful when bearings operate in dirty or moist

environments. The selection of a suitable sealing arrangement depends upon lubricant

types, rotational speeds, operating temperature, available space and so on. Two com-

mon types of sealing, that is contact and non-contact sealing, are used for low speeds

and high speeds, respectively.

In contact sealing, seals directly contact rotating shafts. The presence of seals

increases friction and wear; therefore, the rubbing surfaces should have a high polish.

Figure 11.17a shows a felt seal placed in a machined groove for grease lubrication at

low speeds. The commercial seal is an assembly consisting of elastomer and a spring

backing [14], encased in a counterbored hole in a bearing cover. The opening of a

commercial seal facing a bearing is used to retain lubricant, as shown in Figure 11.17b,