Page 338 - Analysis and Design of Machine Elements

P. 338

Analysis and Design of Machine Elements

316

(a) (b)

(c) (d)

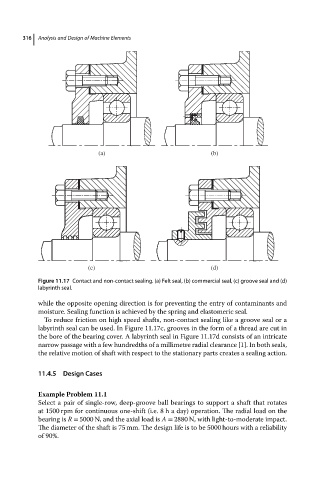

Figure 11.17 Contact and non-contact sealing. (a) Felt seal, (b) commercial seal, (c) groove seal and (d)

labyrinth seal.

while the opposite opening direction is for preventing the entry of contaminants and

moisture. Sealing function is achieved by the spring and elastomeric seal.

To reduce friction on high speed shafts, non-contact sealing like a groove seal or a

labyrinth seal can be used. In Figure 11.17c, grooves in the form of a thread are cut in

the bore of the bearing cover. A labyrinth seal in Figure 11.17d consists of an intricate

narrow passage with a few hundredths of a millimetre radial clearance [1]. In both seals,

the relative motion of shaft with respect to the stationary parts creates a sealing action.

11.4.5 Design Cases

Example Problem 11.1

Select a pair of single-row, deep-groove ball bearings to support a shaft that rotates

at 1500 rpm for continuous one-shift (i.e. 8 h a day) operation. The radial load on the

bearing is R = 5000 N, and the axial load is A = 2880 N, with light-to-moderate impact.

The diameter of the shaft is 75 mm. The design life is to be 5000 hours with a reliability

of 90%.