Page 340 - Analysis and Design of Machine Elements

P. 340

Analysis and Design of Machine Elements

318

Steps Computation Results

6215 6315

The design life of the 6315 bearing is

( )

10 6 f C

t

L 10h = =

60n f P

p

10 6 ( 1 × 113000 ) 3

= 16475 h

60 × 1500 1.2 × 8258

8. Conclusion Select bearing 6315

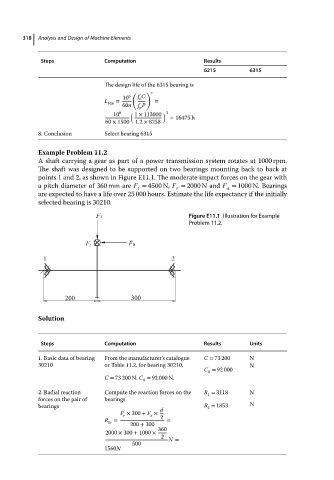

Example Problem 11.2

A shaft carrying a gear as part of a power transmission system rotates at 1000 rpm.

The shaft was designed to be supported on two bearings mounting back to back at

points 1 and 2, as shown in Figure E11.1. The moderate impact forces on the gear with

a pitch diameter of 360 mm are F = 4500 N, F = 2000 N and F = 1000 N. Bearings

t r a

are expected to have a life over 25 000 hours. Estimate the life expectancy if the initially

selected bearing is 30210.

Figure E11.1 Illustration for Example

Problem 11.2.

Solution

Steps Computation Results Units

1. Basic data of bearing From the manufacturer’s catalogue C = 73 200 N

30210 or Table 11.2, for bearing 30210, N

C = 92 000

0

C = 73 200 N, C = 92 000 N.

0

2. Radial reaction Compute the reaction forces on the R = 3118 N

1

forces on the pair of bearings

bearings d R = 1853 N

2

F × 300 + F ×

r a 2

R = =

1v 200 + 300

360

2000 × 300 + 1000 ×

2 N =

500

1560N