Page 335 - Analysis and Design of Machine Elements

P. 335

(a) (b) Rolling Contact Bearings 313

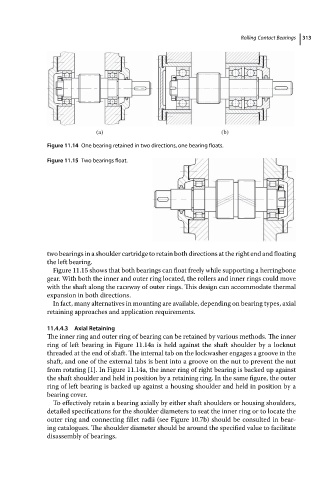

Figure 11.14 One bearing retained in two directions, one bearing floats.

Figure 11.15 Two bearings float.

two bearings in a shoulder cartridge to retain both directions at the right end and floating

the left bearing.

Figure 11.15 shows that both bearings can float freely while supporting a herringbone

gear. With both the inner and outer ring located, the rollers and inner rings could move

with the shaft along the raceway of outer rings. This design can accommodate thermal

expansion in both directions.

In fact, many alternatives in mounting are available, depending on bearing types, axial

retaining approaches and application requirements.

11.4.4.3 Axial Retaining

The inner ring and outer ring of bearing can be retained by various methods. The inner

ring of left bearing in Figure 11.14a is held against the shaft shoulder by a locknut

threaded at the end of shaft. The internal tab on the lockwasher engages a groove in the

shaft, and one of the external tabs is bent into a groove on the nut to prevent the nut

from rotating [1]. In Figure 11.14a, the inner ring of right bearing is backed up against

the shaft shoulder and held in position by a retaining ring. In the same figure, the outer

ring of left bearing is backed up against a housing shoulder and held in position by a

bearing cover.

To effectively retain a bearing axially by either shaft shoulders or housing shoulders,

detailed specifications for the shoulder diameters to seat the inner ring or to locate the

outer ring and connecting fillet radii (see Figure 10.7b) should be consulted in bear-

ing catalogues. The shoulder diameter should be around the specified value to facilitate

disassembly of bearings.