Page 238 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 238

In order to estimate accurately steam generation costs, it is necessary to complete a steam balance on the

plant. An algorithm for carrying out a steam balance for a new facility is listed below.

1. Determine the pressure levels for the steam in the plant. These are usually set at around 41.0 barg

(600 psig), between 10.0 barg (150 psig) and 15.5 barg (225 psig), and between 3.4 barg (50

psig) and 6.1 barg (90 psig).

2. Determine the total number of process users of the different levels of steam. These numbers

become the basis for the steam balance.

3. Determine which of the above users will return condensate to the boiler feed water (BFW)

system. Note: If live steam injection is required for the process, there will be no condensate

returned from this service. In addition, for some small users, condensate return may not be

economical.

4. Determine the condensate-return header pressure.

5. Estimate the blowdown losses.

6. Complete a balance on the steam and condensate, and determine the required water makeup to

the steam system.

7. Determine the steam generating capacity of the steam boiler. The logic used here is that all steam

will be generated at the highest-pressure level and will be let down either through turbines or

let-down stations (valves) to the medium- and low-pressure headers. The high-pressure steam

is often generated at 44.3 barg (650 psig) to allow for frictional losses and superheated to

400°C (752°F) to produce more efficient power production in the turbines.

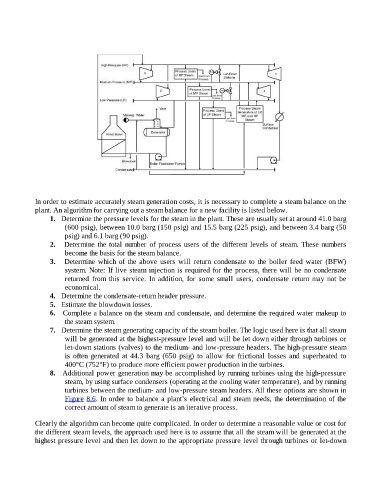

8. Additional power generation may be accomplished by running turbines using the high-pressure

steam, by using surface condensers (operating at the cooling water temperature), and by running

turbines between the medium- and low-pressure steam headers. All these options are shown in

Figure 8.6. In order to balance a plant’s electrical and steam needs, the determination of the

correct amount of steam to generate is an iterative process.

Clearly the algorithm can become quite complicated. In order to determine a reasonable value or cost for

the different steam levels, the approach used here is to assume that all the steam will be generated at the

highest pressure level and then let down to the appropriate pressure level through turbines or let-down