Page 240 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 240

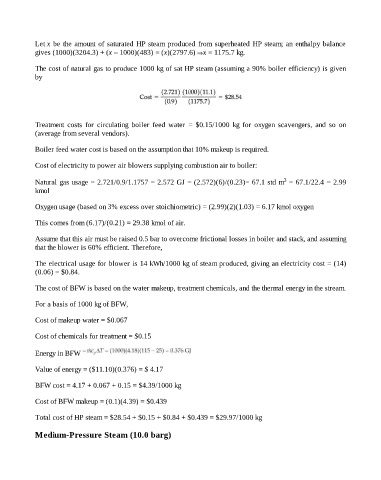

Let x be the amount of saturated HP steam produced from superheated HP steam; an enthalpy balance

gives (1000)(3204.3) + (x – 1000)(483) = (x)(2797.6) x = 1175.7 kg.

The cost of natural gas to produce 1000 kg of sat HP steam (assuming a 90% boiler efficiency) is given

by

Treatment costs for circulating boiler feed water = $0.15/1000 kg for oxygen scavengers, and so on

(average from several vendors).

Boiler feed water cost is based on the assumption that 10% makeup is required.

Cost of electricity to power air blowers supplying combustion air to boiler:

3

Natural gas usage = 2.721/0.9/1.1757 = 2.572 GJ = (2.572)(6)/(0.23)= 67.1 std m = 67.1/22.4 = 2.99

kmol

Oxygen usage (based on 3% excess over stoichiometric) = (2.99)(2)(1.03) = 6.17 kmol oxygen

This comes from (6.17)/(0.21) = 29.38 kmol of air.

Assume that this air must be raised 0.5 bar to overcome frictional losses in boiler and stack, and assuming

that the blower is 60% efficient. Therefore,

The electrical usage for blower is 14 kWh/1000 kg of steam produced, giving an electricity cost = (14)

(0.06) = $0.84.

The cost of BFW is based on the water makeup, treatment chemicals, and the thermal energy in the stream.

For a basis of 1000 kg of BFW,

Cost of makeup water = $0.067

Cost of chemicals for treatment = $0.15

Energy in BFW

Value of energy = ($11.10)(0.376) = $ 4.17

BFW cost = 4.17 + 0.067 + 0.15 = $4.39/1000 kg

Cost of BFW makeup = (0.1)(4.39) = $0.439

Total cost of HP steam = $28.54 + $0.15 + $0.84 + $0.439 = $29.97/1000 kg

Medium-Pressure Steam (10.0 barg)