Page 411 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 411

simulation. The transport and other properties are used in equipment sizing calculations. The techniques

used in the simulators are no more accurate than those covered in transport, thermodynamics, unit

operations, and separations courses—they are just easier to apply.

Even though simple mass and energy balances cannot be done by the simulator without the above-

mentioned pure-component properties, often the most influential decision in a simulation is the choice of a

model to predict phase equilibria. Several of the popular simulators have expert systems to help the user

select the appropriate model for the system. The expert system determines the range (usually with

additional user input) of operating temperatures and pressures covered by the simulation and, with data on

the components to be used, makes an informed guess of the thermodynamic models that will be best for the

process being simulated. The word expert should not be taken too seriously! The expert-system choice is

only a first guess. Additionally, the model chosen may not be best for a given piece of equipment. A

moderately complex simulation will use at least two different thermodynamic packages for different parts

of the flowsheet.

Due to the importance of thermodynamic model selection and the many problems that the wrong selection

leads to, a separate section (Section 13.4) is dedicated to this subject. An example of how the wrong

thermodynamic package can cause serious errors is given in Example 13.1.

Example 13.1

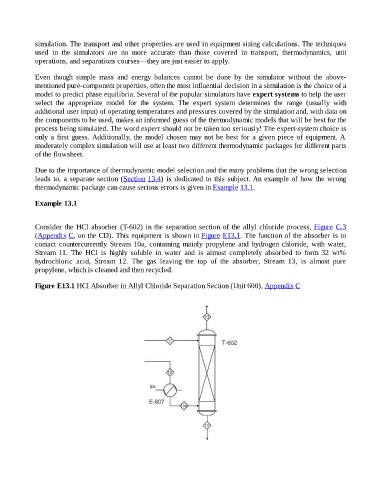

Consider the HCl absorber (T-602) in the separation section of the allyl chloride process, Figure C.3

(Appendix C, on the CD). This equipment is shown in Figure E13.1. The function of the absorber is to

contact countercurrently Stream 10a, containing mainly propylene and hydrogen chloride, with water,

Stream 11. The HCl is highly soluble in water and is almost completely absorbed to form 32 wt%

hydrochloric acid, Stream 12. The gas leaving the top of the absorber, Stream 13, is almost pure

propylene, which is cleaned and then recycled.

Figure E13.1 HCl Absorber in Allyl Chloride Separation Section (Unit 600), Appendix C