Page 86 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 86

needed. This is a viable operation for this separation of benzene and toluene in the HDA process.

Economic considerations often make distillation the separation method of choice. The separation of

benzene and toluene is routinely practiced through distillation and is the preferred method in the

preliminary PFD for this process.

Recycle Feed and Product Together with a Purge Stream. If separation of unreacted feed and

products is not accomplished easily, then recycling both feed and product should be considered. In the

HDA process, the methane product will act as an inert because it will not react with toluene. In addition,

we are not limited by equilibrium considerations; therefore, the reaction of methane and benzene to give

toluene and hydrogen (the undesired path for this reaction), under the conditions used in this process, is

not significant. It should be noted that for the case when a product is recycled with an unused reactant and

the product does not react further, then a purge stream must be used to avoid the accumulation of product

in the process. For the HDA process, the purge is the fuel gas containing the methane product and unused

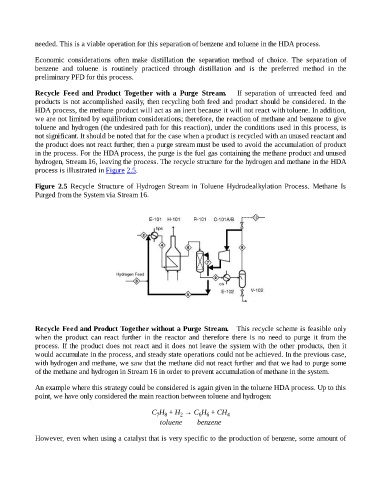

hydrogen, Stream 16, leaving the process. The recycle structure for the hydrogen and methane in the HDA

process is illustrated in Figure 2.5.

Figure 2.5 Recycle Structure of Hydrogen Stream in Toluene Hydrodealkylation Process. Methane Is

Purged from the System via Stream 16.

Recycle Feed and Product Together without a Purge Stream. This recycle scheme is feasible only

when the product can react further in the reactor and therefore there is no need to purge it from the

process. If the product does not react and it does not leave the system with the other products, then it

would accumulate in the process, and steady state operations could not be achieved. In the previous case,

with hydrogen and methane, we saw that the methane did not react further and that we had to purge some

of the methane and hydrogen in Stream 16 in order to prevent accumulation of methane in the system.

An example where this strategy could be considered is again given in the toluene HDA process. Up to this

point, we have only considered the main reaction between toluene and hydrogen:

C H + H → C H + CH 4

2

7 8

6 6

toluene benzene

However, even when using a catalyst that is very specific to the production of benzene, some amount of