Page 123 - Analytical Electrochemistry 2d Ed - Jospeh Wang

P. 123

108 PRACTICAL CONSIDERATIONS

4-5.1 Mercury Electrodes

Mercury is a very attractive choice of electrode material because it has a high

hydrogen overvoltage that greatly extends the cathodic potential window (compared

to solid electrode materials) and possesses a highly reproducible, readily renewable,

and smooth surface. In electrochemical terms, its roughness factor equals unity (i.e.,

identical geometrical and actual surface areas). Disadvantages of the use of mercury

are its limited anodic range (due to the oxidation of mercury) and its toxicity.

There are several types of mercury electrodes. Of these, the dropping mercury

electrode (DME), the hanging mercury drop electrode (HMDE), and mercury ®lm

electrode (MFE) are the most frequently used.

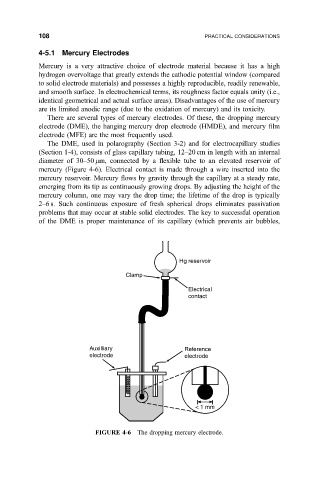

The DME, used in polarography (Section 3-2) and for electrocapillary studies

(Section 1-4), consists of glass capillary tubing, 12±20 cm in length with an internal

diameter of 30±50 mm, connected by a ¯exible tube to an elevated reservoir of

mercury (Figure 4-6). Electrical contact is made through a wire inserted into the

mercury reservoir. Mercury ¯ows by gravity through the capillary at a steady rate,

emerging from its tip as continuously growing drops. By adjusting the height of the

mercury column, one may vary the drop time; the lifetime of the drop is typically

2±6 s. Such continuous exposure of fresh spherical drops eliminates passivation

problems that may occur at stable solid electrodes. The key to successful operation

of the DME is proper maintenance of its capillary (which prevents air bubbles,

Hg reservoir

Clamp

Electrical

contact

Auxilliary Reference

electrode electrode

< 1 mm

FIGURE 4-6 The dropping mercury electrode.