Page 17 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 17

66131_Ludwig_CH10A 5/30/2001 4:06 PM Page 7

Heat Transfer 7

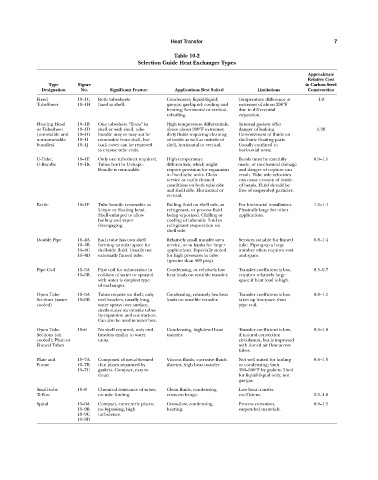

Table 10-2

Selection Guide Heat Exchanger Types

Approximate

Relative Cost

Type Figure in Carbon Steel

Designation No. Significant Feature Applications Best Suited Limitations Construction

Fixed 10—1C Both tubesheets Condensers; liquid-liquid; Temperature difference at 1.0

TubeSheet 10—1H fixed to shell. gas-gas; gas-liquid; cooling and extremes of about 200°F

heating, horizontal or vertical, due to differential

reboiling. expansion.

Floating Head 10—1B One tubesheet “floats” in High temperature differentials, Internal gaskets offer

or Tubesheet 10—1D shell or with shell, tube above about 200°F extremes; danger of leaking. 1.28

(removable and 10—1G bundle may or may not be dirty fluids requiring cleaning Corrosiveness of fluids on

nonremovable 10—1I removable from shell, but of inside as well as outside of shell-side floating parts.

bundles) 10—1J back cover can be removed shell, horizontal or vertical. Usually confined to

to expose tube ends. horizontal units.

U-Tube; 10—1E Only one tubesheet required. High temperature Bends must be carefully 0.9—1.1

U-Bundle 10—1K Tubes bent in U-shape. differentials, which might made, or mechanical damage

Bundle is removable. require provision for expansion and danger of rupture can

in fixed tube units. Clean result. Tube side velocities

service or easily cleaned can cause erosion of inside

conditions on both tube side of bends. Fluid should be

and shell side. Horizontal or free of suspended particles.

vertical.

Kettle 10—1F Tube bundle removable as Boiling fluid on shell side, as For horizontal installation. 1.2—1.4

U-type or floating head. refrigerant, or process fluid Physically large for other

Shell enlarged to allow being vaporized. Chilling or applications.

boiling and vapor cooling of tube-side fluid in

disengaging. refrigerant evaporation on

shell side.

Double Pipe 10—4A Each tube has own shell Relatively small transfer area Services suitable for finned 0.8—1.4

10—4B forming annular space for service, or in banks for larger tube. Piping-up a large

10—4C shell-side fluid. Usually use applications. Especially suited number often requires cost

10—4D externally finned tube. for high pressures in tube and space.

(greater than 400 psig).

Pipe Coil 10—5A Pipe coil for submersion in Condensing, or relatively low Transfer coefficient is low, 0.5—0.7

10—5B coil-box of water or sprayed heat loads on sensible transfer. requires relatively large

with water is simplest type space if heat load is high.

of exchanger.

Open Tube 10—5A Tubes require no shell, only Condensing, relatively low heat Transfer coefficient is low, 0.8—1.1

Sections (water 10—5B end headers, usually long, loads on sensible transfer. takes up less space than

cooled) water sprays over surface, pipe coil.

sheds scales on outside tubes

by expansion and contraction.

Can also be used in water box.

Open Tube 10—6 No shell required, only end Condensing, high-level heat Transfer coefficient is low, 0.8—1.8

Sections (air headers similar to water transfer. if natural convection

cooled); Plain or units. circulation, but is improved

Finned Tubes with forced air flow across

tubes.

Plate and 10—7A Composed of metal-formed Viscous fluids, corrosive fluids Not well suited for boiling 0.8—1.5

Frame 10—7B thin plates separated by slurries, high heat transfer. or condensing; limit

10—7C gaskets. Compact, easy to 350—500°F by gaskets. Used

clean. for liquid-liquid only; not

gas-gas.

Small-tube 10—8 Chemical resistance of tubes; Clean fluids, condensing, Low heat transfer

Teflon no tube fouling. cross-exchange. coefficient. 2.0—4.0

Spiral 10—9A Compact, concentric plates; Cross-flow, condensing, Process corrosion, 0.8—1.5

10—9B no bypassing, high heating. suspended materials.

10—9C turbulence.

10—9D