Page 239 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 239

66131_Ludwig_CH10G 5/30/2001 4:37 PM Page 202

202 Applied Process Design for Chemical and Petrochemical Plants

1,500177.82 valve; the vapor outlet assumes short pipe connection, a 90°

Clean: U c 74.0 welded ell and a fully open gate valve. Reference 73 dis-

77.8 1,500

cusses exchanger piping layout.

Dirty based on total available surface: The outlet vapor line should be two nominal pipe sizes

larger than the liquid inlet. Table 10-33 is helpful to relate

exchanger size and pipe connections, although the same

1,528,600

U D 56.3 standards cannot apply to every design.

145121602

To illustrate the effect of the pressure drop on the

Allowance in selected unit for fouling:

reboiler selection, Table 10-34 compares several designs for

the same heat load and quantity of reboiled vapor.

U c U D 74 56.3

r 0.00425

1742156.32

U c U D

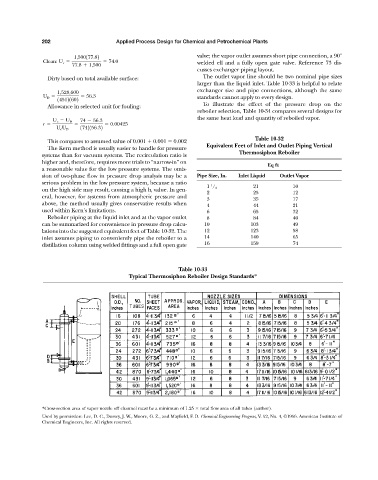

Table 10-32

This compares to assumed value of 0.001 0.001 0.002

Equivalent Feet of Inlet and Outlet Piping Vertical

The Kern method is usually easier to handle for pressure

Thermosiphon Reboiler

systems than for vacuum systems. The recirculation ratio is

higher and, therefore, requires more trials to “narrow-in” on

Eq ft

a reasonable value for the low pressure systems. The omis-

sion of two-phase flow in pressure drop analysis may be a Pipe Size, In. Inlet Liquid Outlet Vapor

serious problem in the low pressure system, because a ratio

1 21 10

1 / 2

on the high side may result, causing a high h i value. In gen-

2 25 12

eral, however, for systems from atmospheric pressure and

3 35 17

above, the method usually gives conservative results when 4 44 21

used within Kern’s limitations. 6 65 32

Reboiler piping at the liquid inlet and at the vapor outlet 8 84 40

can be summarized for convenience in pressure drop calcu- 10 103 49

lations into the suggested equivalent feet of Table 10-32. The 12 123 58

inlet assumes piping to conveniently pipe the reboiler to a 14 140 65

distillation column using welded fittings and a full open gate 16 159 74

Table 10-33

Typical Thermosiphon Reboiler Design Standards*

*Cross-section area of vapor nozzle off channel must be a minimum of 1.25 total flow area of all tubes (author).

Used by permission: Lee, D. C., Dorsey, J. W., Moore, G. Z., and Mayfield, F. D. Chemical Engineering Progress, V. 52, No. 4, ©1956. American Institute of

Chemical Engineers, Inc. All rights reserved.