Page 199 - Applied Petroleum Geomechanics

P. 199

194 Applied Petroleum Geomechanics

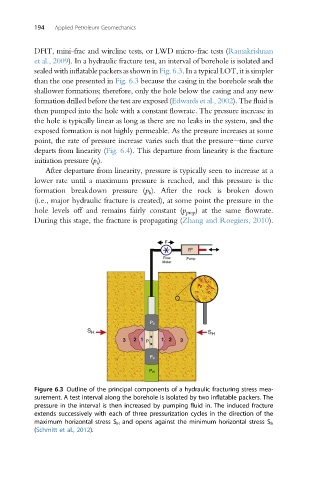

DFIT, mini-frac and wireline tests, or LWD micro-frac tests (Ramakrishnan

et al., 2009). In a hydraulic fracture test, an interval of borehole is isolated and

sealed with inflatable packers as shown in Fig. 6.3. In a typical LOT, it is simpler

than the one presented in Fig. 6.3 because the casing in the borehole seals the

shallower formations; therefore, only the hole below the casing and any new

formation drilled before the test are exposed (Edwardsetal.,2002). The fluid is

then pumped into the hole with a constant flowrate. The pressure increase in

the hole is typically linear as long as there are no leaks in the system, and the

exposed formation is not highly permeable. As the pressure increases at some

point, the rate of pressure increase varies such that the pressureetime curve

departs from linearity (Fig. 6.4). This departure from linearity is the fracture

initiation pressure (p i ).

After departure from linearity, pressure is typically seen to increase at a

lower rate until a maximum pressure is reached, and this pressure is the

formation breakdown pressure (p b ). After the rock is broken down

(i.e., major hydraulic fracture is created), at some point the pressure in the

hole levels off and remains fairly constant (p prop ) at the same flowrate.

During this stage, the fracture is propagating (Zhang and Roegiers, 2010).

Figure 6.3 Outline of the principal components of a hydraulic fracturing stress mea-

surement. A test interval along the borehole is isolated by two inflatable packers. The

pressure in the interval is then increased by pumping fluid in. The induced fracture

extends successively with each of three pressurization cycles in the direction of the

maximum horizontal stress S H and opens against the minimum horizontal stress S h

(Schmitt et al., 2012).