Page 109 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 109

Fluid Flow 95

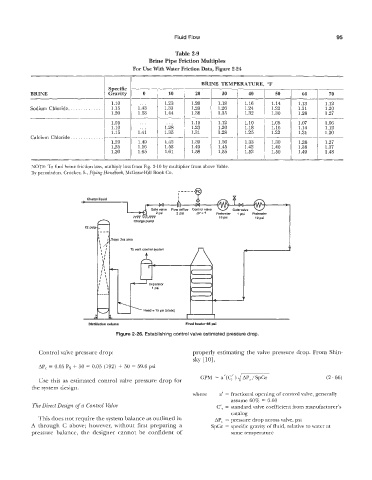

Table 2-9

Brine Pipe Friction Multiples

For Use With Water Friction Data, Figure 2-24

BRINE TEMPERATURE, “F

0 1 10 1 20 I 30 1

1 1.10 ... 1.23 1.20 1.18 1.16 1 1.22 I 1.21 j 1.12

BRINE Gravity 40 50 160-1

70

1.13

1.14

1.32 1

Sodium Chloride.. 1.15 1 i::; I 1.33 1.29 1.26 I 1.24 1.20

1.20 1.44 1.38 1.35 1.30 1.28 1.27

1.05 ... ... 1.15 1.12 1.10 1.08 1.07 1.06

I 1.10 ... 1.28 1.23 1.20 1.18 1.16 1.14 1.12

1.15 1.41 1.35 1.31 1.28 1.25 1.22 1.21 1.20

____ ____

Calcium Chloride. . . . . . . .

1.20 1.49 1.43 1.39 1.36 1.33 1.30 1.28 1.27

1.25 1.56 1.53 1.49 1.45 1.42 1.40 1.38 1.37

1.30 1.65 1.61 1.58 1.55 1.52 1.50 , 1.49 1.48

I I

NOTE: To find brine friction loss, multiply loss from Fig. 2-10 by multiplier from above Table.

By permission, Crocker, S., Piping Handbook, McGraw-Hill Book Go.

Charge liquid

r

22 psi

Trays this area

To vent control system

Separator

1 psi

Head = 15 psi (static)

Dlstillaticn column Fired heater 65 psi

Figure 2-26. Establishing control valve estimated pressure drop.

Control valve pressure drop: properly estimating the valve pressure drop. From Shin-

sky [101,

AP, = 0.05 Ps + 50 = 0.05 (192) -1 50 = 59.6 psi

-

GPM = a’(c%’ 4 (2 - 66)

Use this as estimated control valve pressure drop for )

the system design.

where a‘ = fractional opening of control valve, generally

assume 60% = 0.60

The Direct Oeszgn of a Control Valve C’, = standard valve coefficient from manufacturer’s

catalog

This does not require the system balance as outlined in APc = pressure drop across valve, psi

A through G above; however, without first preparing a SpGr = specific gravity of fluid, relative to water at

pressure balance, the designer cannot be confident of same temperature