Page 114 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 114

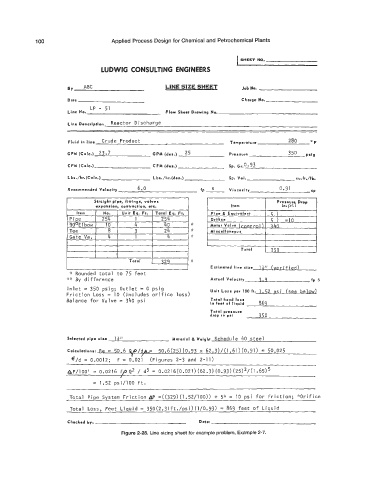

100 Applied Process Design for Chemical and Petrochemical Plants

SHEET NO.

LUDWIG CONSULTING ENGINEERS

BY ABC LINE SIZE SHEET Job No.

Date Charge No.

LP - 51

Line NO. Flow Sheet Drowipg No.

~

~

~i~~ ~ Reactor ~Discharge ~ i ~ ~ i ~ ~

Fluid in line Crude Product Temperature 280 OF

GPM (Calc.) 23.7 GPM (des.) 25 Pres sure 350 psig

CFM (Calc.) CFM (des.) Sp. Gr.O.93 -

L b s . /hr. (C a I c. ) L bs./hr.(des.) sp. VOl. cu.ft./lb.

S

Recommended Velocity 6.0 fP ___ Viscosity 0.91 CP

Straight pipe, fittings, valves Pressure. Drop

expansion, contraction, etc. Item in- pS I

Item No. Unit Eq. Ft. Total Eq. Ft. Pipe B Equivalent 5)

1

Pipe 254 4 254 L Ori fi ce 5 1 =10

s

Mator Valve (control 1 740

40

90OElbow

10

8

3

Tee

24

Mi scellaneaus

4

4

1

Gate Va.

Total i -

1

1

1

I

I

Total

f Rounded total to 75 feet !c Estimated line size erif ied)

By difference Actual Velocity 3.9 fp s

Inlet = 350 psig; Outlet = 0 psig Unit Lass per 100 ft. 1.52 Dsi (see below]

Friction Loss = 10 (includes orifice loss)

Balance for Valve = 340 psi Total head loss 869

in feet of liquid

Total pressure

drop in psi 350

Selected pipe sire 14" Material 8 Weight Schedule 40 steel

Calculations: Re = 50.6 QP/ dL= 50.6(25) (0.93 x 62.3)/(1.61) (0.91) = 50,025

b/d = 0.0012; f = :.02: (Figures 2-3 and 2-11)

AP/lOO' = 0,0216 f/3 Q2 / d5 = 0.0216(0.021) (62.3) (0.93) (25)*/(1.65)5

4

= 1.52 psi/lOO ft.

Total Pipe System Friction =((329)(1.52/100)) + 5" = 10 psi for friction; "Orifice

Total Loss, Feet Liquid = 350(2.3lft./psi)(l/0.93) = 869 feet of Liquid

Checked by: Dote:

Figure 2-28. Line sizing sheet for example problem, Example 2-7.