Page 120 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 120

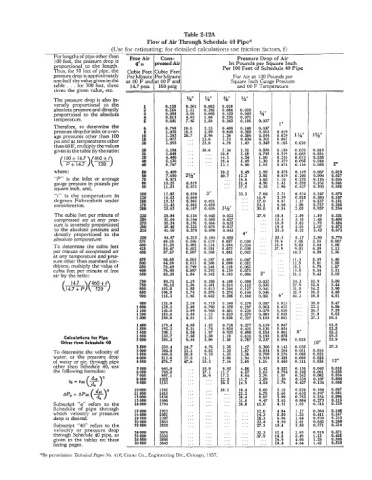

Table 2-12A

Flow of Air Through Schedule 40 Pipe*

(Use for estimating; for detailed calculations use friction factors, f)

-

_______- ..- -. .

.

For lengths of pipe other than Free A~ Com- Pressure Drop of Air

100 feet, the pressure drop is n'

roportional -to the length. wm ressed& In Pounds per Square Inch

hus, for 50 feet of pipe, the Cubic Feet bbic Feet Per 100 Feet of Schedule 40 Pipe

presshe drop is approxhately Per Minute 'er Minute For Air at 100 Pounds per

one-half the value given in the at 60 F and t 60 F and Square Inch Gauge Pressure

table . . . for 300 feet, three 14.7 psia 100 psig - - __ - - - - -

and 60 F Temperature

__. - -

-

-

-

times the given value, etc. - - - -

The pressure drop is also in- w '/s 3/s" YZn

versely proportional to the 1 0.128 0.361 0.083 0.018

absolute pressure and directly 2 0.256 1.31 0.285 0.064 0.020

.proportional to the absolute 3 0.384 3.06 0.605 0.133 0.042 W"

0.071

temperature. 4 0.513 4.83 1.04 0.226 0.106 0.027

7.45

0.641

1.58

0.343

5

Therefore, to determine the 6 0.769 10.6 2.23 0.408 0.148 0.037 1"

pressure drop for inlet or aver- 8 1.025 18.6 3.89 0.848 0.255 0.062 0.019

age pressures other than 100 10 1.282 28.7 5.96 1.26 0.356 0.094 0.029 11A" 1%"

...

0.062

psi and at temperatures other 15 1.922 ... 13.0 2.73 0.834 0.201 0.102 0.026

0.345

2.563

L2.8

1.43

20

4.76

than 60 F, multiply the values

7.34

given in the table by the ratio: 25 3.204 ... 55.6 10.5 2.21 0.526 0.156 0.039 0.019

...

...

0.219

0.026

0.055

3.15

0.748

30

3.845

...

...

100 + 14.7

460 + i

( P+ 14.7 )(m) 35 4.486 ... ... 14.2 4.24 1.00 0.293 0.073 0.035 2*

5.126

0.095

1.30

5.49

40

0.379

18.4

0.044

...

...

0.474

1.62

0.055

6.90

13.1

0.116

5.767

45

where: so 6.408 18.5 8.49 1.99 0.578 0.149 0.067 0.019

...

"P" is the inlet or average 60 7.690 2%" L0.7 12.2 2.85 0.819 0.200 0.094 0.027

3.63

0.270

0.126

16.5

0.036

1.10

70

8.971

gauge pressure in pounds per 80 10.25 0.019 ... 21.4 4.96 1.43 0.350 0.162 0.046

...

square inch, and, 90 11.53 0.023 27.0 6.25 1.80 0.437 0.203 0.058

7.69

"t" is the temperature in 100 12.82 0.029 3 I' 33.2 11.9 2.21 0.534 0.247 0.070

...

0.380

0.825

0.107

3.39

16.02

0.044

125

degrees Fahrenheit under 150 19.22 0.062 0.021 ... 17.0 4.87 1.17 0.537 0.151

consideration. 175 22.43 0.083 0.028 ... 13.1 6.60 1.58 0.727 0.205

200 25.63 0.107 0.036 31/2" ... 30.0 8.54 2.05 0.937 0.264

The cubic feet per minute of 22s 28.84 0.134 0.045 0.022 37.9 10.8 2.59 1.19 0.331

compressed air at any pres- 250 32.04 0.164 0.055 0.027 ... 13.3 3.18 1.45 0.404

...

1.75

sure is inversely proportional 275 35.24 0.191 0.066 0.032 ... 16.0 3.83 2.07 0.484

19.0

0.573

4.56

0.078

0.037

38.45

300

0.232

to the absolute pressure and 325 41.65 0.270 0.090 0.043 ... 12.3 5.32 2.42 0.673

directly proportional to the 4" ...

absolute temperature. 350 44.87 0.313 0.104 0.050 0.030 ... 15.8 6.17 2.80 0.776

0.887

0.057

0.119

0.356

19.6

375

3.20

7.05

48.06

To determine the cubic feet 400 51.26 0.402 0.134 0.064 0.034 ... 33.6 8.02 3.64 1.00

...

1.13

9.01

per minute of compressed air 425 54.47 0.452 0.151 0.072 0.038 ... 37.9 10.2 4.09 1.26

...

57.67

0.168

4.59

0.042

0.507

450

0.081

at any temperature and pres-

0.047

11.3

sure other than standard con- 475 60.88 0.562 0.187 0.089 0.052 ... 12.5 5.09 1.40

...

0.099

5.61

1.55

0.206

64.08

0.623

500

ditions, multiply the value of 550 70.49 0.749 0.248 0.118 0.062 ... 15.1 6.79 1.87

cubic feet per minute of free 600 76.90 0.887 0.293 0.139 0.073 ... 15.0 8.04 2.21

...

air by the ratio: 650 83.30 1.04 0.342 0.163 0.086 5" 21.1 9.43 2.60

+

700

89.71

P

14.7

0.036

3.44

12.6

27.9

0.113

0.451

1.36

750

(X)(%%$) 96.12 1.19 0.395 0.188 0.099 0.032 24.3 10.9 3.00

0.214

800 102.5 1.55 0.513 0.244 0.127 0.041 31.8 14.2 3.90

850 108.9 1.74 0.576 0.274 0.144 0.046 35.9 16.0 4.40

900 115.3 1.95 0.642 0.305 0.160 0.051 6" 40.2 18.0 4.91

950 121.8 2.18 0.715 0.340 0.178 0.057 0.023 ... 20.0 5.47

1000 128.2 2.40 0.788 0.375 0.197 0.063 0.025 ... 22.1 6.06

...

1100 141.0 2.89 0.948 0.451 0.236 0.075 0 030 26.7 7.29

1 200 153.8 3.44 1.13 0.533 0.279 0.089 0: 035 ... 31.8 8.63

1300 166.6 4.01 1.32 0.626 0.327 0.103 0.041 ... 37.3 10.1

1 400 179.4 4.65 1.52 0.718 0.377 0.119 0.047 11.8

1 500 192.2 5.31 1.74 0.824 0.431 0.136 0.054 13.5

1 600 205.1 6.04 1.97 0.932 0.490 0.154 0.061 8 I' 15.3

1 800

Calculations for Pipe 2000 230.7 7.65 2.50 1.18 0.616 0.193 0.075 0.023 19.3

0.094

23.9

9.44

256.3

0.757

3.06

0.237

1.45

Other than Schedule 40 10"

2 500 320.4 14.7 4.76 2.25 1.17 0.366 0.143 0.035 37.3

To determine the velocity of 3000 384.5 21.1 6.82 3.20 1.67 0.524 0.204 0.051 0.016

0.022

0.068

0.709

9.23

3 500

water, or the pressure drop 4000 448.6 28.8 12.1 4.33 2.26 0.919 0.276 0.088 0.028

512.6

2.94

37.6

5.66

0.358

of water or air, through pipe 4 500 576.7 47.6 15.3 7.16 3.69 1.16 0.450 0.111 0.035 12*

other than Schedule 40, use ... 4.56 1.42 0.552 0.136 0.043 0.018

8.85

the following formulas: 5 000 640 8 ... 18.8 12.7 6.57 2.03 0.794 0.195 0.061 0.025

769:O

27.1

6 000

7 000 897.1 ... 36.9 17.2 8.94 2.76 1.07 0.262 0.082 0.034

8000 1025 ... ... 22.5 11.7 3.59 1.39 0.339 0.107 0.044

9 000 1153 ... ... 28.5 14.9 4.54 1.76 0.427 0.134 0.055

10 000 1282 ... ... 35.2 18.4 5.60 2.16 0.526 0.164 0.067

11 OOO 1410 ... ... ... 22.2 6.78 2.62 0.633 0.197 0.081

12 OOO 1538 ... ... ... 26.4 8.07 3.09 0.753 0.234 0.096

...

...

...

0.112

1666

0.884

0.273

3.63

31.0

9.47

Subscript "a" refers to the 13 000 1794 ... ... ... 36.0 11.0 4.21 1.02 0.316 0.129

14 OOO

Schedule of pipe through 15 OOO 1922 ... ... ... ... 12.6 4.84 1.17 0.364 0.148

which velocity or pressure 16 OOO 2051 ... ... ... ... 14.3 5.50 1.33 0.411 0.167

drop is desired. 18 000 2307 ... ... ... ... 22.4 6.96 1.68 0.520 0.213

18.2

...

...

...

...

2.01

2563

0.260

0.642

8.60

Subscript "40" refers to the 20 000 2820 ... ... ... ... 27.1 10.4 2.50 0.771 0.314

22 000

velocity or pressure drop ... ... ... ... 0.371

through Schedule 40 pipe, as 24 OOO 3076 ... ... ... ... 32.3 12.4 2.97. 0.918 0.435

14.5

37.9

3332

26 000

3.49

1.12

given in the tables on these 28 000 3588 ... ... ... ... ... 16.9 4.04 1.25 0.505

...

...

..I

0.520

1.42

facing pages. 30 000 3845 ... ... 19.3 4.64 - -

I_

*By permission Technical Paper No. 410, Crane Co., Engineering Div., Chicago, 1957.