Page 21 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 21

10 Applied Process Design for Chemical and Petrochemical Plants

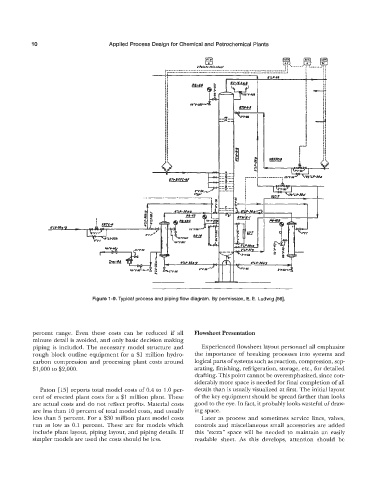

percent range. Even these costs can be reduced if all Flowsheet Presentation

minute detail is avoided, and only basic decision making

piping is included. The necessary model structure and Experienced flowsheet layout personnel all emphasize

rough block outline equipment for a $1 million hydro- the importance of breaking processes into systems and

carbon compression and processing plant costs around logical parts of systems such as reaction, compression, sep-

$1,000 to $2,000. arating, finishing, refrigeration, storage, etc., for detailed

drafting. This point cannot be overemphasized, since con-

siderably more space is needed for final completion of all

Paton [15] reports total model costs of 0.4 to 1.0 per- details than is usually visualized at first. The initial layout

cent of erected plant costs for a $1 million plant. These of the key equipment should be spread farther than looks

are actual costs and do not reflect profits. Material costs good to the eye. In fact, it probably looks wasteful of draw-

are less than 10 percent of total model costs, and usually ing space.

less than 5 percent. For a $30 million plant model costs Later as process and sometimes service lines, valves,

run as low as 0.1 percent. These are for models which controls and miscellaneous small accessories are added

include plant layout, piping layout, and piping details. If this “extra” space will be needed to maintain an easily

simpler models are used the costs should be less. readable sheet. As this develops, attention should be