Page 263 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 263

Mechanical Separations 235

Table 4-7

General Applications of Liquid Particle Separators

Gravity I Impinge- COLLECTOR TYPES

Opesat ion concentration I Particle Sizes ment Cyclone Scrubbers Electrical

Pipeline entrained liquid light fine to coarse No Frequent Yes Occasional Few

Compressor discharge liquid light fine No Frequent Occasional Occasional Rare

Compressor oil haze very light very fine NO Frequent Frequent Frequent Occasional

Flashing liquid light to mod. fine to medium No Frequent Frequent Occasional Rare

Boiling or bubbling light to heavy fine to coarse Occasional Frequent Frequent Qccasional Rare

Spraying light to heavy fine to coarse NO Frequent Frequent Rare Rare

Corrosive liquid particles light to heavy fine to coarse Occasional Frequent Occasional

Liquid plus solid particles light to heavy medium Occasional Occasional Frequent

"."

I

0.0001 0.001 0.8 0. I .0 10 100 1,000 10, 100,000 I,000,000

I

DpPu

Reynolds Number, NRe = -

B

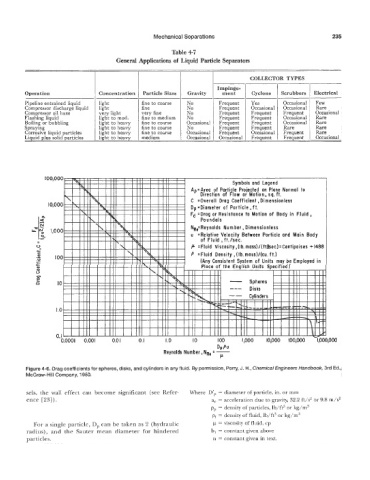

Figure 4-6. Drag coeffici'ents for spheres, disks, and cylinders in any fluid. By permission, Perry, d. H., Chemical Engineers Handbook, 3rd Ed.,

McGraw-Hill Company, 11 956).

sels, the wall effect can become significant (see Refer- Where D', = diameter of particle, in. or mm

ence [23]). a, = acceleration due to gravity, 32.2 ft/s2 or 9.8 m/s2

p, = density of particles, lb/ft3 or kg/m3

pf = density of fluid, Ib/ft3 or kg/m3

For a single particle, D, can be taken as 2 (hydraulic ~1 = viscosity of fluid, cp

radius), and the Sauter mean diameter for hindered bl = constant given above

particles. n = constant given in text.