Page 268 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 268

240 Applied Process Design for Chemical and Petrochemical Plants

for assumed spherical particles in a surfactant-free system The minimum residence time as determined by

[26]. The minimum particle diameter for many fine dis- Stokes’ Law terminal settling velocity is:

persions is 100 microns; however, Reference [28] has

reviewed a wide variety of liquid drop data and suggests

that a good choice is 150 micron or 0.15 cm or 0.0005 ft.

This is also the particle size used in the API Design Manu-

al [24]. Using too large an assumed particle diameter will h, = height of segment of circle, in.

cause the settler unit to become unreasonably small.

V, = terminal settling velocity, in./min

Assuming a horizontal unit, as illustrated in Figure 4

11, has a segment of a circle equal to 25% to 75% [27,26]

of the circular area (the highest of this segment will be Average residence time related to minimum residence

about 30% to 70% of the diameter), then height of the time is:

interface will be [26]:

H/D = 0.8A/(.irD2/4) + 0.1, ft (415)

f = factor relating average velocity to maximum velocity

or, h, = 38.4A/(.rrD) + 1.2D, in (415A)

where H = height of segment of a circle, ft This relationship is related to the viscosities of the

hydrocarbon and aqueous phases at the interface. Based

h, = height of segment of a circle, in.

on data from different systems:

D = diameter of vessel, ft

A = area of segment of circle, sq ft

f = 2.0 (use for design)

The average volumetric residence time in the settler is:

The active volume occupied by either phase is:

LVg = 7.48 (Vset/F), min (416)

v = AL, cu ft (419)

V,,, = active volume of settler occupied by one of the phases,

cu ft

L = length of vessel, ft, inlet to outlet

F = flow rate of one phase GPM

= average residence time based on liquid flow rate and ves-

sel volume, min h, = ’7.48 ALx,/(fF) (420)

Water alternate makeup

L )I

HC inlet-HC outlet Washed hydrocarbon

Hydrocarbon Mixer

to be washed (in4 i ne)

plus water

LC

- --

7

I

I

I

I t Alternate blowdown

*Velocity < 1 O”/min hA I c

I

I

Aqueous circulation 4

‘’ ‘7’ disposal

Blowdown,to

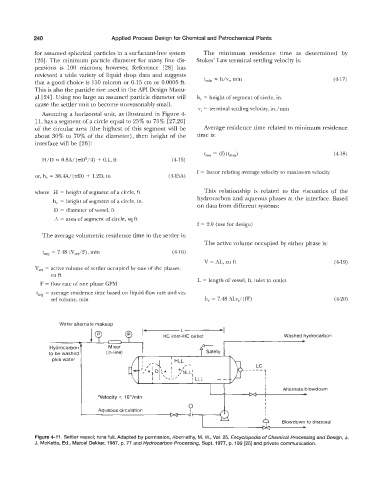

Figure 4-11. Settler vessel; runs full. Adapted by permission, Abernathy, M. W., Vol. 25, Encyclopedia of Chemical Processing and Design, J.

J. McKetta, Ed., Marcel Dekker, 1987, p. 77 and Hydrocarbon Processing, Sept. 1977, p. 199 [25] and private communication.