Page 271 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 271

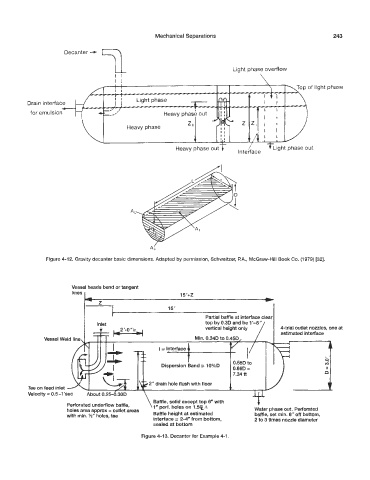

Mechanical Separations 243

Decanter 4

light phase

Drain interface

6.-

for emulsion

Heavy phase out

f l

A

4

Figure 4-12. Gri?ivity decanter basic dimensions. Adapted by permission, Schweitzer, P.A., McGraw-Hill Book Co. (1 979) [32].

Vessel heads bend or tangent

lines

Partial baffle at interface clear

top by 0.3D and be 1’4”

vertical height only &trial outlet nozzles, one at

estimated interface

Vessel Weld line

Tee on feed inlet -

Velocity = 0.5-l’sec

Baffle, solid except top 6” with c

erforated underflow baffle, \ 1“ perf. holes on 1.5% A

holes area approx = outlet areas Water phase out. Perforated

height at estimated baffle, set min. 6” off bottom,

with min. lh’’ holes, tee interface 24” from bottom, 2 to 3 times nozzle diameter

sealed at bottom

Figure 4-13. Decanter for Example 4-1.