Page 282 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 282

254 Applied Process Design for Chemical and Petrochemical Plants

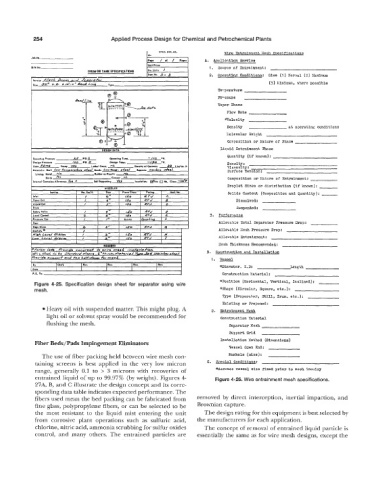

'dire ?htra,inaont Xesh SDecifications

A. Applicntion Service

uni, Pric.

VU No. 1. Source of 3ntrainment:

DRUM OR TANK SPECIFICAT~NI n -

I.." Y.. 2. Operatin7 Conditions: Give (1) Formal (2) &.ximum

(3) I<inirrm, where possible

Te:.oerature

Pr-ssure

Vapor Phase

Flow Rate

*Vel0 ci ty

Density at operatin_r conditions

i .o le cular Yeirht

Coiposition or Kature of Pbse

Lipaid Zntninaent Phase

Quantity (if known) :

Dens1 ty :

ViocositJ:

Surface Tension:

Composition or Uiture of Entrainnent:

Droglet Sizes or distribution (if known):

Solids Content (Composition and Quantity):

Dissolved:

3r;spended:

3. Perfornance

AllonaSle Totil Separator Pressure Dro?:

Allowable Xesh Pressure Drop:

Allorrible Entralment :

Yeah Thickness Recomended:

E. Construction and Installation

BY 1 ChhY I I.". I I... I R.V. I h.. I 1. Vessel Lensth

*Dia*ae t er . I. D:

I.* I I I I I

P.O. T.: Construction Yaterial:

+Position (Eorizontal, Vertical, Inclined):

Figure 4-25. Specification design sheet for separator using wire

mesh. +Shape (Circular, Square, etc.):

Type (5'vepor3tor, Still, Drum. etc.):

Existing or Proposed:

Heavy oil with suspended matter. This might plug. A 2. ESltrsim.ent Nesh

light oil or solvent spray would be recommended for Construction Xaterial

flushing the mesh. Separator Kesh

Support Grid

Fiber Beds/Pads Impingement Eliminators Installation Kethod (Dlaensions)

Vessel Open End:

The use of fiber packing held between wire mesh con- &$anhole (size):

taining screens is best applied in the very low micron C. S?ecial Conditions:

range, generally 0.1 to > 3 microns with recoveries of *Assumes vessel size fixed prior to mesh lnoulry

entrained liquid of up to 99.9'7% (by weight). Figures 4 Figure 4-26. Wire entrainment mesh specifications.

27A, B, and C illustrate the design concept and its corre-

sponding data table indicates expected performance. The

fibers used mean the bed packing can be fabricated from removed by direct interception, inertial impaction, and

fine glass, polypropylene fibers, or can be selected to be Brownian capture.

the most resistant to the liquid mist entering the unit The design rating for this equipment is best selected by

from corrosive plant operations such as sulfuric acid, the manufacturers for each application.

chlorine, nitric acid, ammonia scrubbing for sulfur oxides The concept of removal of entrained liquid particle is

control, and many others. The entrained particles are essentially the same as for wire mesh designs, except the