Page 301 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 301

Mechanical Separations 273

r,orn Dust c. Chemical composition of vapor and of dust,

Sources including any abrasive, hydroscopic or other char-

acteristics.

2. Define dust recovery, as percentage below a certain

particle size.

3. Indicate, if known, preferred bag material that

will withstand environment, e.g., fibers of glass,

polyester, Teflon@, Nomex@, polypropylene, poly-

ethylene, cotton, wool, nylon, Qrlon@, Dacron@,

and Dynel@. The type of weave of fiber should be

recommended by the manufacturer. The fabrics

may be felted or woven [4$,48] in weaves of

plain, satin, or twill, and should be resistant to

to Fan

to Fan

k any corrosive material in the solid particles or

Cleaning Air from the gas stream.

~ ~ ~ a s ~ h ~ g ~

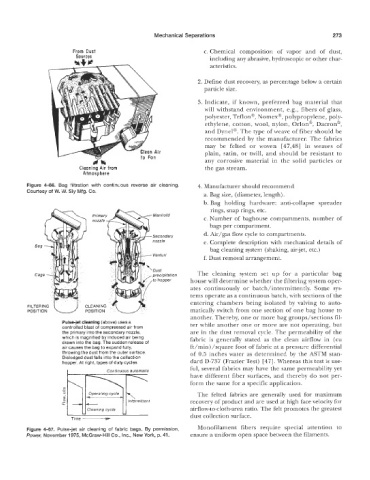

th continuous reverse air cleaning. 4. Manufacturer should recommend

a. Bag size, (diameter, length).

b. Bag holding hardware: anti-collapse spreader

rings, snap rings, etc.

Manjrold

c. Number of baghouse compartments, number of

bags per compartment.

d. Air/gas flow cycle to compartments.

Secondary

nozzle e. Complete description with mechanical details of

bag cleaning system (shaking, air-jet, etc.)

Venturi

f. Dust removal arrangement.

Dust The cleaning system set up for a particular bag

precipitation

to hopper house will determine whether the filtering system oper-

ates continuously or batch/intermittently. Some sys-

tems operate as a continuous batch, with sections of the

entering chambers being isolated by vahing to auto-

FIL TERING

POSITION L/ POSITION matically switch from one section of one bag house to

another. Thereby, one or more bag groups/sections fil-

ulse-jet cleaning (above) uses a ter while another one or more are not operating, but

controlled blast of compressed air from

the primary into the secondary nozzle, are in the dust removal cycle. The permeability of the

which IS magnified by induced air being fabric is generally stated as the clean airflow in (cu

arawn into the bag The sudden release of

air causes the bag to expand fully ft/min) /square foot of fabric at a pressure differential

throwing the dust from the outer surface of 0.5 inches water as determined by the ASTM stan-

Dislodged dust falls into the collection

hopper Pit right, types of duty cycles dard D-737 (Frazier Test) [47]. Whereas this test is use-

ful, several fabrics may have the same permeability yet

I Continuous automafic

have different fiber surfaces, and thereby do not per-

form the same for a specific application.

The felted fabrics are generally used for maximum

recovery of product and are used at high face velocity for

airflow-to-cloth-area ratio. The felt promotes the greatest

dust collection surface.

Time

cleaning of fabric bags. By permission, Monofilament fibers require special attention to

cGraw-Hill Go., Inc., New York, p. 41. ensure a uniform open space between the filaments.