Page 304 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 304

276 Applied Process Design for Chemical and Petrochemical Plants

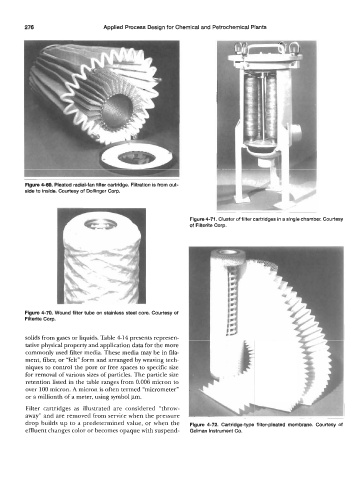

Figure 4-69. Pleated radial-fan filter cartridge. Filtration is from out-

side to inside. Courtesy of Dollinger Cow.

Figure 4-71. Cluster of filter cartridges in a single chamber. Courtesy

of Filterite Corp.

Figure 4-70. Wound filter tube on stainless steel core. Courtesy of

Filterite Corp.

solids from gases or liquids. Table 414 presents represen-

tative physical property and application data for the more

commonly used filter media. These media may be in fila-

ment, fiber, or "felt" form and arranged by weaving tech-

niques to control the pore or free spaces to specific size

for removal of various sizes of particles. The particle size

retention listed in the table ranges from 0.006 micron to

over 100 micron. A micron is often termed "micrometer"

or a millionth of a meter, using symbol pm.

Filter cartridges as illustrated are considered "throw-

away" and are removed from service when the pressure

drop builds up to a predetermined value, or when the Figure 4-72. Cartridge-type filter-pleated membrane. Courtesy of

effluent changes color or becomes opaque with suspend- Gelman Instrument Co.