Page 308 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 308

280 Applied Process Design for Chemical and Petrochemical Plants

PLAIN OR SQUARE DUTCH WEAVE

Equivalent

Standard

Microns Microns

10 40

20 55

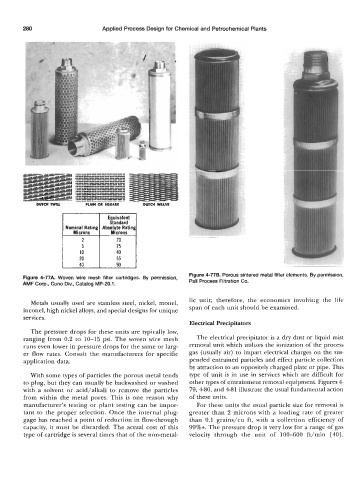

Figure 4-77B. Porous sintered metal filter elements. By permission,

Figure 4-77A. Woven wire mesh filter cartridges. By permission,

AMF Corp., Cuno Div., Catalog MP-20.1. Pall Process Filtration Co.

lic unit; therefore, the economics involving the life

Metals usually used are stainless steel, nickel, monel,

inconel, high nickel alloys, and special designs for unique span of each unit should be examined.

sei-vices.

Electrical Precipitators

The pressure drops for these units are typically low,

ranging from 0.2 to 10-15 psi. The woven wire mesh The electrical precipitator is a dry dust or liquid mist

runs even lower in pressure drops for the same or larg- removal unit which utilizes the ionization of the process

er flow rates. Consult the manufacturers for specific gas (usually air) to impart electrical charges on the sus-

application data. pended entrained particles and effect particle collection

by attraction to an oppositely charged plate or pipe. This

With some types of particles the porous metal tends type of unit is in use in services which are difficult for

to plug, but they can usually be backwashed or washed other types of entrainment removal equipment. Figures 4

with a solvent or acid/alkali to remove the particles 79, 480, and 481 illustrate the usual fundamental action

from within the metal pores. This is one reason why of these units.

manufacturer's testing or plant testing can be impor- For these units the usual particle size for removal is

tant to the proper selection. Once the internal plug- greater than 2 microns with a loading rate of greater

gage has reached a point of reduction in flow-through than 0.1 grains/cu ft, with a collection efficiency of

capacity, it must be discarded. The actual cost of this 99%~ The pressure drop is very low for a range of gas

type of cartridge is several times that of the non-metal- velocity through the unit of 100-600 ft/min [40].