Page 309 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 309

Mechanical Separations 281

I

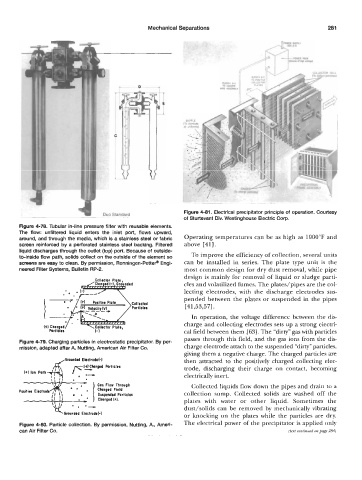

Duo Standard Figure 4-81. Electrical precipitator principle of operation. Courtesy

of Sturtevant Div. Westinghouse Electric Corp.

Figure 4-78. Tubular in-line pressure filter with reusable elements.

The flow: unfiltered liquid enters the inlet port, flows upward,

around, and through the media, which is a stainless steel or fabric Operating temperatures can be as high as 1000°F and

screen reinforced by a perforated stainless steel backing. Filtered above [41].

liquid discharges through the outlet (top) port. Because of outside-

to-inside flow path, solids collect on the outside of the element so To improve the efficiency of collection, several units

screens are easy to clean. By permission, Ronningen-Pettep Engi- can be installed in series. The plate type unit is the

neered Filter Systems, Bulletin RP-2. most common design for dry dust removal, while pipe

design is mainly for removal of liquid or sludge parti-

coII*ctor PIott

cles and volatilized fumes. The plates/pipes are the col-

lecting electrodes, with the discharge electrodes sus-

pended between the plates or suspended in the pipes

[41,53,57].

In operation, the voltage difference between the dis-

charge and collecting electrodes sets up a strong electri-

cal field between them [63]. The “dirty” gas with particles

passes through this field, and the gas ions from the dis-

Figure 4-79. Charging particles in electrostatic precipitator. By per-

mission, adapted after A. Nutting, American Air Filter Co. charge electrode attach to the suspended “dirty” particles,

giving them a negative charge. The charged particles are

,Grounded Ekstrodd-1 then attracted to the positively charged collecting elec-

trode, discharging their charge on contact, becoming

i! ii . e electrically inert.

. Gas Flow Thrauqh Collected liquids flow down the pipes and drain to a

Charged Field

,I !I *-• I SusDendtd Particles collection sump. Collected solids are washed off the

. -* ) Cho;qed(+L plates with water or other liquid. Sometimes the

dust/solids can be removed by mechanically vibrating

or knocking on the plates while the particles are dry.

Figure 4-80. Particle collection. By permission, Nutting, A., Ameri- The electrical power of the precipitator is applied only

can Air Filter Co. (text continued on page 284)