Page 296 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 296

268 Applied Process Design for Chemical and Petrochemical Plants

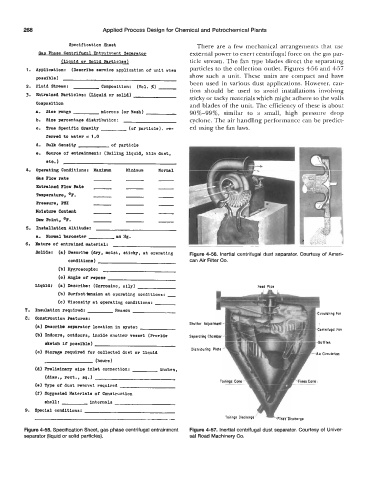

Specification Sheet There are a few mechanical arrangements that use

ms Phase Centrlfuaal htrainient Se-ssrator external power to exert centrifugal force on the gas par-

JLlouid or Solid Particles1 ticle stream. The fan type blades direct the separating

1. Application: (Describe service application of unit vken particles to the collection outlet. Figures 4-56 and 4-57

show such a unit. These units are compact and have

ponsible)

been used in various dust applications. However, cau-

2. Fluid Stream: Composition: (Vol. $)

tion should be used to avoid installations involving

3. Entrained Partlcler: (Llquld or solid) sticky or tacky materials which might adhere to the walls

Composlt ion and blades of the unit. The efficiency of these is about

a. Sire range microns (or Mesh) 90%-99%, similar to a small, high pressure drop

b. Size percentage dlrtrlbution: cyclone. The air handling performance can be predict-

o. True Specific Qravlty (of particle), re- ed using the fan laws.

ferred to water = 1.0

d. Bulk denslty of particle

e. Souroe of entrainaent: (Boiling liquid, kiln dust,

eto. 1

4. Operatlng Condition.: Iraxlmum Hinimum soma1

Gar Flow rate -

&trained Plow Rate -

Temperature, OF. -

Presrure, PSI

Holrture Content -

DOU point, OF. - -

5. Inatallation Altitude:

a. Noma1 barometer mi He.

6. Nature of entrained material:

Bolldo: (a) Dercribe (dry, moist, sticky, at operating Figure 4-56. Inertial centrifugal dust separator. Courtesy of Ameri-

condltlonr ) can Air Filter Co.

(b) Hygroscopic:

(0) Angle of repose

LlqOld: (a) Describe: (Corrosive, oily) Feed Pipe

(b) Surfacttonalon at operating condltions: -

(c) Viscosity at operating conditions:

-8

7. Innulation required: Reason Circulating Fan

e; Conrtmction Featurer:

Shulter Adjustment -

(a) Dercrlbe repnrator location in systeq ntrifugal Fan

(b) Indoorr, outdoors, inside another vessel (Provide Seperating Chamber -

Qetch ir porslble) iffles

Distributing Plate’

(0) Storage required for collected dust or liquid -Air Circulation

(hours)

(d) Preliminary eize inlet connection: inches,

(diam., rect., sq.)

nes Cone

(e) Type of duet removal requlred

(f) Swgested Haterials of Constrwtlon

shell: internal8

9. Special conditions:

.- .- Tailings Discharge ’ ‘Fines Discharge

Figure 4-55. Specification Sheet, gas phase centrifugal entrainment Figure 4-57. Inertial centrifugal dust separator. Courtesy of Univer-

separator (liquid or solid particles). sal Road Machinery Co.