Page 293 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 293

Mechanical Separations 265

VmpartDut T

Inlet

.._. .+.-

(Also Designed to Wrap

98. to 180’ Around Vessel

Io give Tangential Inlrtl.

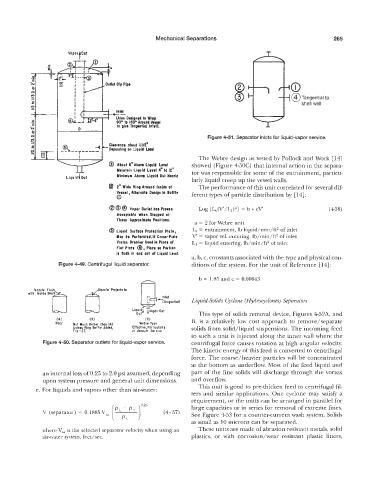

Figure 4-51. Separator inlets for liquid-vapor service.

The Webre design as tested by Pollock and Work [ 141

@ About 6” Above Liquid Level showed (Figure 450C) that internal action in the separa-

Maintain Liquid Level 4“ to 12“ tor was responsible for some of the entrainment, particu-

LiQuid b 10ut Minimum Above Liquid Out Nozzle larly liquid creep up the vessel walls.

2* Wide Ring Around lnridr at The performance of this unit correlated for several dif-

Vnsrd , Altcrnotr Design 10 Baffle ferent types of particle distribution by [14]:

Q

8 @ @ Vapor Outlet has Proven Log [&.(V’/Ll)a] = b t cV’ (458)

Acceptable when Stopped at

Theta Approximata Positions.

a = 2 for Webre unit

0 Liquid Surface Protection Plate, L, = entrainment, lb liquid/min/ft2 of inlet

May be Perforatd.lf Cross-Plate V‘ = vapor vel. entering, Ib/min/ft2 of inlet

Vartrr Ereoker Used in Place of L, = liquid entering, lb/min/ft2 of inlet

Place

Flat plate 0, sa Portion

i5 Both in ond out of Liquid Lmvel.

a, b, c, constants associated with the type and physical con-

igure 4-49. Centrifugal liquid separator. ditions of the system. For the unit of Reference [14]:

b = 1.85 and c = 0.00643

Nozzle Flus ozrla Projects in

with Inside She

Inlet

c Liquid-Solids Cyclone (Hydrocyclones) Separators

ITonqentiall

Liqui out

ou This type of solids removal device, Figures 452A, and

(AI IB) IC) B, is a relatively low cost approach to remove/separate

Not Much Eeiler than (AI Webre Type

Unless Ring Boffle Added, Effective, Particulaily solids from solid/liquid suspensions. The incoming feed

Fig. - 27. in Vacuum Service

to such a unit is injected along the inner wall where the

Figure 4-50. Sep,arator outlets for liquid-vapor service. centrifugal force causes rotation at high angular velocity.

The kinetic energy of this feed is converted to centrifugal

force. The coarse/heavier particles will be concentrated

at the bottom as underflow. Most of the feed liquid and

an internal loss of 0.25 to 2.0 psi assumed, depending part of the fine solids will discharge through the vortex

upon system pressure and general unit dimensions. and overflow.

This unit is good to pre-thicken feed to centrifugal fil-

e. For liquids and vapors other than air-water:

ters and similar applications. One cyclone may satisfj a

requirement, or the units can be arranged in parallel for

large capacities or in series for removal of extreme fines.

See Figure 453 for a counter-current wash system. Solids

as small as 10 microns can be separated.

where Vsa is the selected separator velocity when using an These units are made of abrasion resistant metals, solid

air-water system, feet/sec. plastics, or with corrosion/wear resistant plastic liners,