Page 289 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 289

Mechanical Separations 261

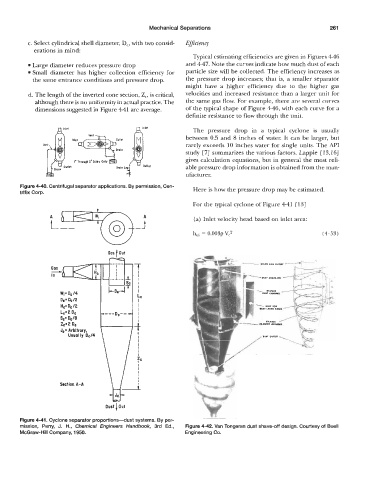

c. Select cylindrical shell diameter, D,, with two consid-

erations in mind:

Typical estimating efficiencies are given in Figures 446

Large diameter reduces pressure drop and 447. Note the curves indicate how much dust of each

Small diameter has higher collection efficiency for particle size will be collected. The efficiency increases as

the same entrance conditions and pressure drop. the pressure drop increases; that is, a smaller separator

might have a higher efficiency due to the higher gas

d. The length of the inverted cone section, Z,, is critical, velocities and increased resistance than a larger unit for

although there is no uniformity in actual practice. The the same gas flow. For example, there are several curves

dimensions suggested in Figure 4-41 are average. of the typical shape of Figure 446, with each curve for a

definite resistance to flow through the unit.

The pressure drop in a typical cyclone is usually

between 0.5 and 8 inches of water. It can be larger, but

rarely exceeds 10 inches water for single units. The API

study [7] summarizes the various factors. Lapple [13,16]

gives calculation equations, but in general the most reli-

able pressure drop information is obtained from the man-

ufac turer.

Figure 4-40. Centrifugal separator applications. By permission, Cen- Here is how the pressure drop may be estimated.

trifix Corp.

For the typical cyclone of Figure 441 [ 131

(a) Inlet velocity head based on inlet area:

hUi = 0.003~ Vc2 (4-53)

Gas 1 Out

r'9

T

I

I

I

De

Wi : /4 I

Des &/2 I I kc

He= De 12

Lc'2 De

Sc'De/S

Zc'2 Dc

J,- Arbitrary,

Usually Dc/4

Section A-A

Figure 4-41. Cyclone separator proportions-dust systems. By per-

mission. Perry, J. H., Chemical Engineers Handbook, 3rd Ed., Figure 4-42. Van Tongeran dust shave-off design. Courtesy of Buell

McGraw-Hill Company, 1950. Engineering Co.