Page 33 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 33

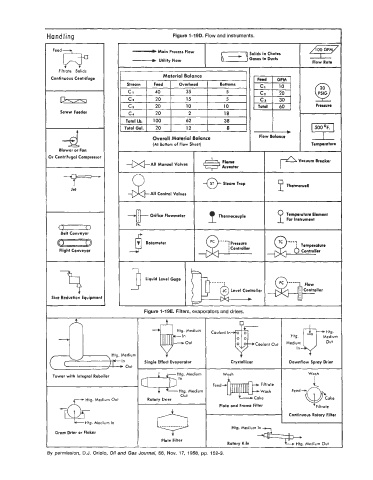

Hand ling Figure 1-19D. Flow and instruments.

FeedB Gases in Ducts Flow Rate

Main

- Flow

Process

Solids in Chutes

___) Utility Flow

Filtrate

Solids

I

Continuous Centrifuge Material Balance

Stream Feed Overhead 1 Bottoms

Cl I 40 1 35 5 I T; @

C, I 20 I 15 I 5

kzzl

Total Presrun

Screw Feeder t-G

-d Overall Material Balance Flow Balance 500 OF.

Blower or Fan (At Bottom of Flow Sheet) Temporature

Or Centrifugal Compressor *All Manual Volves I ,$ Arrortor Vacuum Breaker

Fkmr

- Thermocouple P For Instrument

-

--f)- Orifice Flowmeter 1

I Jet All Control Valves -@- Steam Trap P Thermowell

Temporaturr Element

Belt Conveyor

T Rotameter

Flight Conveyor 4 (J-A n Temperature

Controller

F, Liquid Level Gage &)+ j Controller

Size Reduction Equipment

Figure 1-19E. Filters, evaporators and driers.

+;rum - I

I

Single Effect Evoporator Crystallizer Downflaw Spray Drier

Htg. Medium Wash Wash

Tower with Integral Reboiler i

Feed

astn Medium

out

Htg.

Htg. Medium Out Rotary Drier

Plate and Frome Filter Filtrate

Continuous Rotary Filter

-@ Medium In Htg. Medium In

Htg.

I Drum Drier or Flaker Plate Filter Rotary Kiln Htg. Medium Out

+

By permission, B.J. Oriolo, Oil and Gas Journal, 56, Nov. 17, 1958, pp. 152-3.