Page 35 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 35

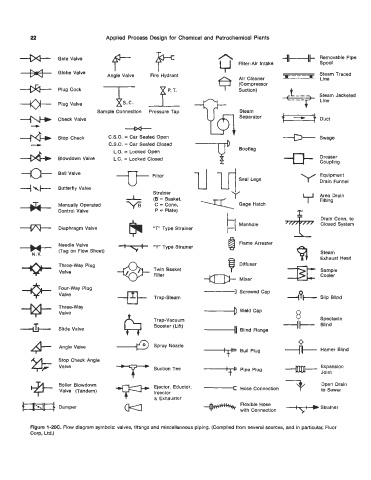

22 Applied Process Design for Chemical and Petrochemical Plants

f+ LrJ Filter-Air Intake Spool

Gate Valve A ++#-. Removable Pipe

.* Globe Valve

Angle Valve Fire Hydrant Air Cleaner -r - - --r Steam Traced

Line

-

& Plug Cock 8 (Compressor

P.

T.

Suction)

-++ Plug Valve Steam Jacketed

Line

Sample Connection Pressure Tap Steam L---+

Check Valve Separator fzf

Duct

--w

4

C.S.O. = Car Sealed Open

Check

Stop

--c C.S.C. = Car Sealed Closed & Swage

L.O. = Locked Open Bootleg

Blowdown Valve L.C. = Locked Closed Dresser

Coupling

Ball Valve

--.fF- Filter Seal Legs

U

4 \+ Butterfly Valve

Strainer Y

(B = Basket,

C= Cone, < ’ Gage Hatch

P = Plate)

$r “T” Type Strainer L

Closed System

Diaphragm Valve b Manhole Drain Conn. to

Needle Valve @ Flame Arrester

“Y”

on

(Tag

* Flow Sheet) ‘w Type Strainer

N.V. Steam

Three-way Plug F Diffuser Exhaust Head

Twin Basket

Valve Filler a Sample

+

Cooler

Four-Way Plug Mixer

Valve Trap-Steam 3 Screwed Cap

Three-way -0

Valve Weld Cap

Trap-Vacuum

5 Slide Valve 4 -11 Blind Flange Spectacle

Booster (Lift)

Blind

Angle Valve Spray Nozzle *-$-

’f Plug Hamer Blind

Bull

Stop Check Angle

T ’t’

Suction Tee

Pipe

Boiler Blowdown Ejector, Eductor,

Valve (Tandem) -E Hose Connection

Injector

& Exhauster

aa

tTii+ Damper ,Tb

Strainer

Figure 1-20C. Flow diagram symbols: valves, fittings and miscellaneous piping. (Compiled from several sources, and in particular, Fluor

Corp, Ltd.)