Page 34 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 34

Process Planning, Scheduling and Flowsheet Design 21

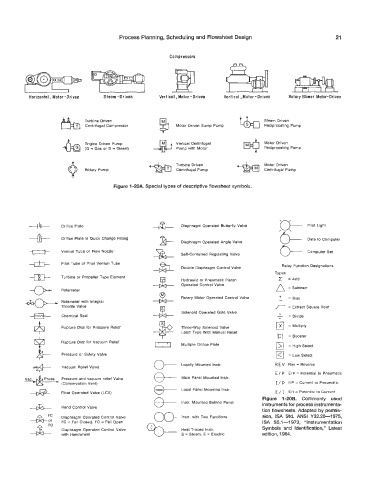

Compressors

Horizontal Motor-Driven Steam -Driven Vertical ,Motor -Driven Vertical, Motor -Driven Rotary Blower Motor-Driven

Turbine Driven Steam Driven

Centrifugal Compressor Motor Driven Sump Pump Reci procati ng P u m p

Engine Driven Pump Vertical Centrifugal Motor Driven

(G = Gas or D = Diesel) Pump with Motor Reciprocating Pump

Turbine Driven Motor Driven

Rotary Pump Centrifugal Pump Centrifugal Pump

Figure 1 -20A. Special types of descriptive flowsheet symbols.

‘e

--+I+- Orifice Plate +?+ Diaphragm Operated Butterfly Valve Pilot Light

---&-- Orifice Plate in Quick Change Fitting &- Diaphragm Operated Angle Vaive Data to Computer

e Self-Contained Regulating Valve Computer Set

Venturi Tube or Flow Nozzle

4

Pitot Tube or Pitot Venturi Tube

Double Diaphragm Control Valve Relay Function Designations

Types

Turbine or Propeller Type Eiement

Hydraulic or Pneumatic Piston =Add

Operated Control Valve

Rotameter = Subtract

2%- - = Bias

Rotary Motor Operated Control Valve

+

Rotameter with Integral

Thrott!e Vaive = Extract Square Root

Solenoid Operated Gate Valve

Chemical Seal - = Divide

Rupture Disc for Pressure Relief Three-way Solenoid Valve I_lrl = Multiply

Latch Type With Manual Reset

1:) = ~ooster

Rupture Disc for Vacuum Relief

Multiple

v] Orifice Plate I>/ = High Select

Pressure or Safety Valve l<r = Low Select

Locally Mounted Instr. R E V Rev = Reverse

Vacuum Relief Valve

@--- E/ P EIP = Potential to Pneumatic

Press. Pressure aind vacuum relief Valve Main Panel Mounted lnstr.

(Conservation Vent) I / p IIP = Current to Pneumatic

Local Panel Mounted Instr.

Float Operated Valve (LCV) E / I Ell = Potential io Current

Figure 1 -2OB. Commonly used

a- Instr. Mounted Behind Panel

Wand Control Valve instruments for process instrumenta-

tion flowsheets. Adapted by permis-

4: Diaphragm Operated Control Vaive Instr. with Two Functions sion, ISA Std. ANSI V32.20-1975,

ISA S5.1-1973, “Instrumentation

FC = Fail Closed, FO = Fail Open

Diaphragm Operated Controi Valve Heat Traced Instr. Symbols and Identification,” Latest

with Handvvheel S = Steam, E = Electric edition, 1984.