Page 105 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 105

94 Applied Process Design for Chemical and Petrochemical Plants

Drickamer and Bradford curve, E, = 46% 1. Assume or set condenser liquid product temperature,

O’Connell curve, E, = 53.8% tD.

2. Calculate condensing pressure, with tD as bubble

In this case, recommend using: point (if subcooling exists, and tD is below bubble

point, use bubble point temperature for pressure cal-

E, e (46 + 53.8)/2 = 49.6% culation only).

3. Vi = L + D

Actual trays in column:

+

HlVl= [L h~ + D h~] (8-184)

Nact = 20/0.496 = 40.3 trays

-

From tray-by-tray calculations, feed tray is 10/0.496 = (8 185)

20.1 trays from bottom, use 20.

Generally, practice would be to select a column allowing

a few extra trays, making column total trays = 45.

No.

Rectifying trays = 22

Feed =1 4. Calculate tl and xi by dew point on vapor VI. Then

Stripping =22

45 determine HI, referring to top tray as number one in

this case.

Feed nozzles should be located on trays Nos. 21,23, and where HI= total vapor enthalpy above reference datum

25 counting up from the bottom tray as No. 1. for sum of all contributing percentages of

individual components, i, in stream, Btu/lb,

Heat Balan-Mjacent Key sgstems with Sharp or Btu/mol

Separations, Constant Molal Overflow hD = total liquid enthalpy above reference datum

for sum of all contributing percentages of

Total Conhser Duty individual components, i, in product stream.

(Also same as reflux), Btu/lb or Btu/mol.

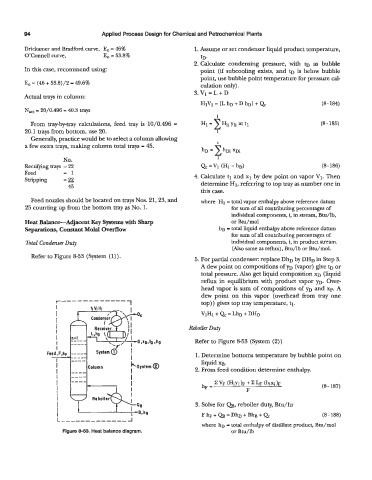

Refer to Figure 8-53 (System (1)).

5. For partial condenser: replace DhD by DHD in Step 3.

A dew point on compositions of yD (vapor) give tD or

total pressure. Also get liquid composition XD (liquid

reflux in equilibrium with product vapor YD. Over-

head vapor is sum of compositions of n, and xp. A

dew point on this vapor (overhead from tray one

I------------- 1 top)) gives top tray temperature, tl.

Reboiler Duty

Refer to Figure 8-53 (System (2))

1. Determine bottoms temperature by bubble point on

liquid XB.

2. From feed condition determine enthalpy.

3. Solve for Qg, reboiler duty, Btu/hr

L ___---------- F hF + QJ = DhD + BhB + Qc (8 - 188)

J

where hn = total enthalpy of distillate product, Btu/mol

-

*.

Figure 8-53. Heat balance diagram. or Btu/lb