Page 230 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 230

Distillation 21 9

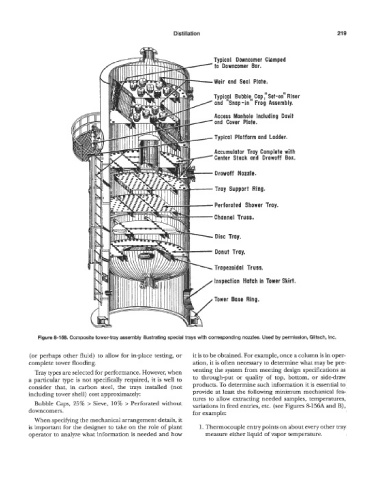

Typical Downcomer Clamped

to Downcomer Bar.

Weir and Seal Plate,

Typic$ Bubbkl Cap:'Set-oil Riser

and Snap-in Frog Assembly.

Access Manhole Including Davit

and Cover Plate.

Typical Platform and Ladder.

Accumulator Tray Complete with

Center Stack and Drawoff BOX.

Drawoff Nozzle.

Tray Support Ring.

Perforated Shower Tray.

Channel Truss.

Disc Tray.

Donut Tray.

Tra pezoida I Truss.

Inspection Hatch in Tower Skirt.

Tower Base Ring.

Figure 8-658. Composite tower-tray assembly illustrating special trays with corresponding nozzles. Used by permission, Glitsch, Inc.

(or perhaps other fluid) to allow for in-place testing, or it is to be obtained. For example, once a column is in oper-

complete tower flooding. ation, it is often necessary to determine what may be pre-

venting the system from meeting design specifications as

Tray types are selected for performance. However, when

a particular type is not specifically required, it is well to to through-put or quality of top, bottom, or side-draw

consider that, in carbon steel, the traj7s installed (not products. To determine such information it is essential to

including tower shell) cost approximately: provide at least the following minimum mechanical fea-

tures to allow extracting needed samples, temperatures,

Bubble Caps, 25% > Sieve, 10% > Perforated without variations in feed entries, etc. (see Figures 8-156A and B),

downcomers. for example:

When specifjmg the mechanical arrangement details, it

is important for the designer to rake on the role of plant 1. Thermocouple entry points on about every other tray

operator to analyze what information is needed and how measure either liquid of vapor temperature.