Page 225 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 225

21 4 Applied Process Design for Chemical and Petrochemical Plants

90

80

70

c.

$

860

E

€50

ci

g40

92

30

2

a

20

10

0

0 1 2 3 4 5 6

ZF

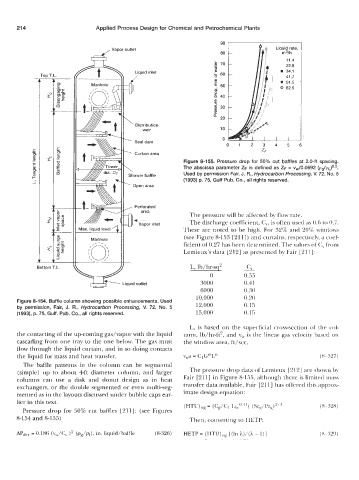

Figure 8-155. Pressure drop for 50% cut baffles at 2.04 spacing.

The abscissa parameter ZF is defined as ZF = vw/0.0692 (~s/pl)O.~.

Used by permission Fair, J. R., Hydrocarbon Processing, V. 72. No. 5

(1 993) p. 75, Gulf Pub. Co., all rights reserved.

The pressure will be affected by flow rate.

The discharge coefficient, C,, is often used as 0.6 to 0.7.

These are noted to be high. For 32% and 20% windows

(see Figure 8-153 [211]) and curtains, respectively, a coef-

ficient of 0.27 has been determined. The values of C, from

Lemieux's data [212] as presented by Fair [211]:

Bottom T.L. L, lb/hr-sq2 ~ c,.

0 0.55

l + p Liquid outlet 3000 0.41

6000 0.30

10,000 0.20

Figure 8-154. Baffle column showing possible enhancements. Used 12,000 0.15

by permission, Fair, J. R., Hydrocarbon Processing, V. 72, No. 5

(1993), p. 75, Gulf. Pub. Co., all rights reserved. 15,000 0.15

L, is based on the superficial cross-section of the col-

the contacting of the up-coming gas/vapor with the liquid umn, lb/hr-f(', and v,~ is the linear gas velocity based on

cascading from one tray to the one below. The gas must the window area, ft/sec,

flow through the liquid curtain, and in so doing contacts

the liquid for mass and heat transfer. vwa = C1G"'L" (8 - 327)

The baffle patterns in the column can be segmental

(simple) up to about 4ft diameter column, and larger The pressure drop data of Lemieux [212] are shown by

columns can use a disk and donut design as in heat Fair [211] in Figure 8-155, although there is limited mass

exchangers, or the double segmented or even multi-seg- transfer data available, Fair [211] has offered this approx-

mented as in the layouts discussed under bubble caps ear- imate design equation:

lier in this text.

(HTU),, = (C,/C, L~,co~") (ScK/I'rK)'''' (8- :32x)

Pressure drop for 50% cut baffles [211]: (see Figures

8-154 and 8-155) Then, converting to HETP:

Lipdry = 0.186 (v,,/c, )2 (&/PI), in. liquid/baffle (8-326)