Page 224 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 224

Distillation 21 3

I

V Load

Tower Area

System Limit

Flooding

Downcomer

Backup

Downcomer Flooding

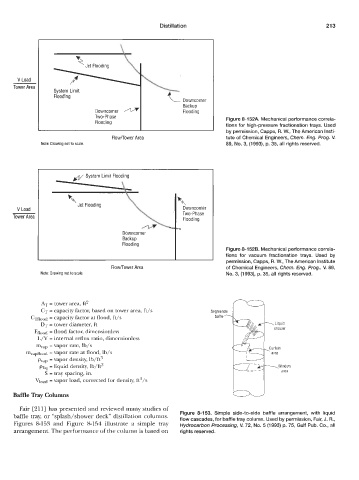

Two-Phase Figure 8-152A. Mechanical performance correla-

tions for high-pressure fractionation trays. Used

by permission, Capps, R. W., The American Insti-

Flowflower Area tute of Chemical Engineers, Chem. Eng. frog. V.

Note: Drawing not to scale. 89, No. 3, (1993), p. 35, all rights reserved.

‘t\

V Load Downcomer

Two-Phase

Tower Area

Flooding

%

Downcomer

Backup

Flooding

Figure 8-1528. Mechanical performance correla-

tions for vacuum fractionation trays. Used by

permission, Capps, R. W., The American Institute

Flowflower Area of Chemical Engineers, Chem. Eng. frog., V. 89,

Note: Drawing not to scale. No. 3, (1993), p. 35, all rights reserved.

AT = tower area, ft2

CT = capacity factor, based on tower area, ft/s Segmental

CTflood = capacity factor at flood, ft/s baffle-

DT = tower diameter, ft

Fflood = flood factor, dimensionless

L/V = internal reflux ratio, dimensionless

m,,, = vapor rate, lb/s

mVapflood = vapor rate at flood, lb/s

pvap = vapor density, lb/ft3

pliq = liquid density, lb/ft3

S = tray spacing, in.

Vload = vapor load, corrected for density, ft3/s

Baffle Tray Columns

Fair [211] has presented and reviewed many studies of

baffle tray, or “splash/shower deck distillation columns. Figure 8-153. Simple side-to-side baffle arrangement, with liquid

Figures 8-153 and Figure 8-154 illustrate a simple tray flow cascades, for baffle tray column. Used by permission, Fair, J. R.,

Hydrocarbon Processing, V. 72, No. 5 (1 993) p. 75, Gulf Pub. Co., all

arrangement. The performance of the column is based on rights reserved.