Page 60 - Assurance of Sterility for Sensitive Combination Products and Materials

P. 60

studies, environmental and

Autoclave IOQ, temperature

gowning and personnel

mapping, BI studies, air

personnel monitoring,

Air profile studies, risk

assessment, training,

disinfectant efficacy

qualification aseptic

removal studies

testing

room sanitization, airflow,

conditions, properly sized

workflow, people flow …

principles, smoke studies

monitoring/recording,

Clean room design, clean

filters, training, first air

of components, clean

Autoclave design, cycle

patterns, automated

receipt and storage

established loading

ingredient storage

component and

Control strategies

random loading patterns,

conditions, incorrect or

Poor aseptic and gowning

Inadequate temperature

incorrect components

excessive bioburden,

air in system, steam

and exposure time,

Process variables

technique

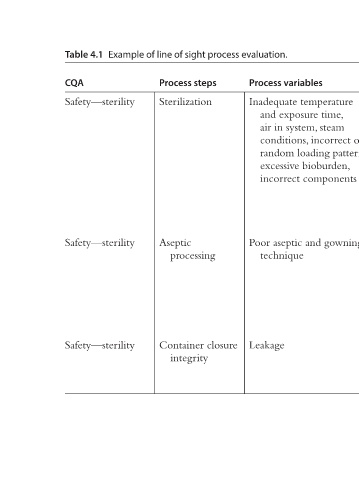

Example of line of sight process evaluation. 48 Qualification/validation Assurance of sterility for sensitive combination products and materials process simulations Design qualification, vendor Container/closure design, Leakage Container closure audit, incoming inspection, sealing process control, integrity leak detecti

Process steps

processing

Sterilization

Aseptic

Table 4.1 CQA Safety—sterility Safety—sterility Safety—sterility