Page 119 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 119

2

Engine systems 103

Figure 2.37 Cylinder layouts and power strokes per engine revolution

4 cylinder in-line ‘V’ 2 cylinder

horizontally opposed

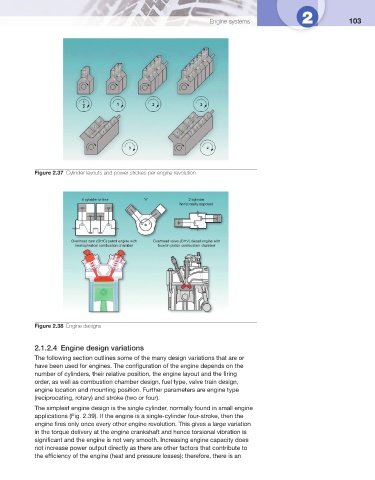

Overhead cam (OHC) petrol engine with Overhead valve (OHV) diesel engine with

hemispherical combustion chamber bowl in piston combustion chamber

Figure 2.38 Engine designs

2.1.2.4 Engine design variations

The following section outlines some of the many design variations that are or

have been used for engines. The confi guration of the engine depends on the

number of cylinders, their relative position, the engine layout and the fi ring

order, as well as combustion chamber design, fuel type, valve train design,

engine location and mounting position. Further parameters are engine type

(reciprocating, rotary) and stroke (two or four).

The simplest engine design is the single cylinder, normally found in small engine

applications ( Fig. 2.39 ). If the engine is a single-cylinder four-stroke, then the

engine fi res only once every other engine revolution. This gives a large variation

in the torque delivery at the engine crankshaft and hence torsional vibration is

signifi cant and the engine is not very smooth. Increasing engine capacity does

not increase power output directly as there are other factors that contribute to

the effi ciency of the engine (heat and pressure losses); therefore, there is an